12m×10m×7m peaked roof bolt truss with 3m side speaker wings—professional outdoor stage roof for concerts, festivals & events.

3m×3m×3m portable aluminum bolt truss booth. Quick-setup box truss display for exhibitions, trade shows, DJ booths & promotions.

5m×5m×5m lightweight aluminum booth truss system. Quick-setup exhibition display truss for trade shows, events & retail promotions.

16m×9m×6m pyramid-shaped aluminum stage roof truss. Professional sloped roof design for concerts, fashion shows & outdoor events. Fast assembly.

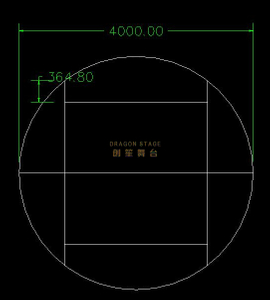

19.52m×19.52m professional aluminum stage platform, built with 1.22×2.44m panels, adjustable legs 0.4–2.0m, includes 2 access stairs.

20m×18m×8m aluminum curved roof truss with 6 main pillars and 2×2m side speaker wings and 2x3m led wings. Perfect for concerts, festivals & large outdoor stages.

Professional 20m×18m×8m aluminum roof truss system with spigot connection. Ideal for large outdoor events, concerts, festivals & stage lighting rigs.

20m×20m heavy-duty aluminum roof truss with 3 long-span beams, designed for a large LED screen, line array & lighting of Layher stage truss system.

it is 2x1m deck for Durable & Adjustable Portable Platform Stage Event Concert, total sizes are 14x10m with 2 Stairs

it is 2x1m stage platform for Aluminum Performance Stage for Large Event, the whole stage sizes are 11x8m with 2 stairs

this is 2x1m stage deck for Wedding Fashion Show Outdoor Concert Stage Platform Aluminum, the total sizes are 12x11m with 2 stairs

18U rolling flight case with 6 drawers + detachable side table. Heavy-duty mobile workstation for makeup, tattoo, DJ & tech tools.

this is 2x1m deck for Aluminum Concert Wedding Assemble Stage Platform 18x8m with 2 stairs

this is 2x1m Modular Outdoor Performance Brace Stage, total sizes are 9m long and 6m wide with 2 stairs

it is 2x1m modular stae for 10x9m Aluminium Customized Design Stage With 2 Stairs

2x1m stage platform for Aluminum Portable Decent Stage for Outdoor Events 12x9m with 2 stairs

this set of line array system is Custom made high quality neodymium components. Most of materials are imported abroad, The design can refer to D&B J8 line array; The subwoofer refer to B22 from D&B.

our 2x1m stage deck for Event Concert Dj Wedding Mobile Portable Stage for Sale 9x4m with 2 stairs

it is 2x1m deck for Portable Aluminum Alloy and Plywood Stage for Events and Concerts 16x9m with 2 stairs

it is 2x1m Event Skidproof Plywood Portable Stage Platform for total sizes of 12x10m with 2 Stairs.

Single Portable Simple Church Stage Designs 10x6m Height 1.2-2m

it is 2x1m stage deck for Aluminum Alloy Wedding Event Adjustable Stage Platform Outdoor, the overall sizes are 11x10m with 2 stairs

it is 2x1m stage deck for Outdoor Aluminum Portable Stage Event Stage, the whole sizes are 18x10m with 2 Stairs

it is 2x1m deck for Aluminum Stage Platform for Outdoor Events Concerts And Weddings 20x8m with 2 stairs

it is 2x1m modular stage for Heavy Loading Portable Mobile Easy Install Event Stage 16x8m with 2 stairs

The Aluminum Indoor Portable Church Stage, measuring 14x9 meters, is a remarkable addition to any religious establishment. This stage offers a versatile and convenient solution for churches seeking to enhance their worship experience.

this is mobile stage 2x1m for Mobile Portable Aluminum Event Stages 18x7m with 2 Stairs

it is 2x1m stage deck for Aluminum Outdoor Indoor Easy Install Recyclable Portable Movable Modular Event Stage. the total sizes are16x12m with 2 stairs.

this is Outdoor Event Show Concert Aluminum Wedding Stage Wooden Platform with total sizes 12x12m and 2 stairs

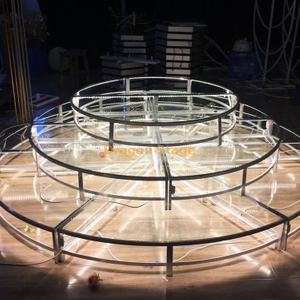

The Elevated Dual-Level Modular Platform is a versatile, truss-supported structure designed for events, festivals, and temporary venues. Featuring two spacious deck levels with integrated bench seating on the lower tier and open upper deck for VIP viewing or equipment, this custom-engineered solution ensures safety, accessibility, and rapid deployment. Supported by robust vertical trusses and equipped with a secure side staircase, it maximizes space efficiency while maintaining structural integrity. Ideal for concerts, sports events, outdoor activations, or production zones, this portable platform adapts to diverse site requirements. Built for durability and ease of assembly, it’s the premium choice for event organizers seeking elevated functionality and audience engagement. Fully customizable—contact us to tailor dimensions, capacity, and finishes to your project.

Structural Manufactured Lighting Cheap Trusses 6x6x6m spigot truss 290x290mm

The aluminum portable concert stage equipment podium is a crucial component in the world of live performances. With its lightweight and durable design, it provides a reliable platform for artists to showcase their talent.

Precision-engineered custom pitch roof truss structure for major outdoor events. 8m Wide, 7m Deep, 5m High. Ideal for concerts, festivals, and high-impact productions. Durable, safe, and modular.

it is 2x1m for Event Catwalk Concert Podium Aluminum Stage, total sizes are 11x4m with 2 Stairs