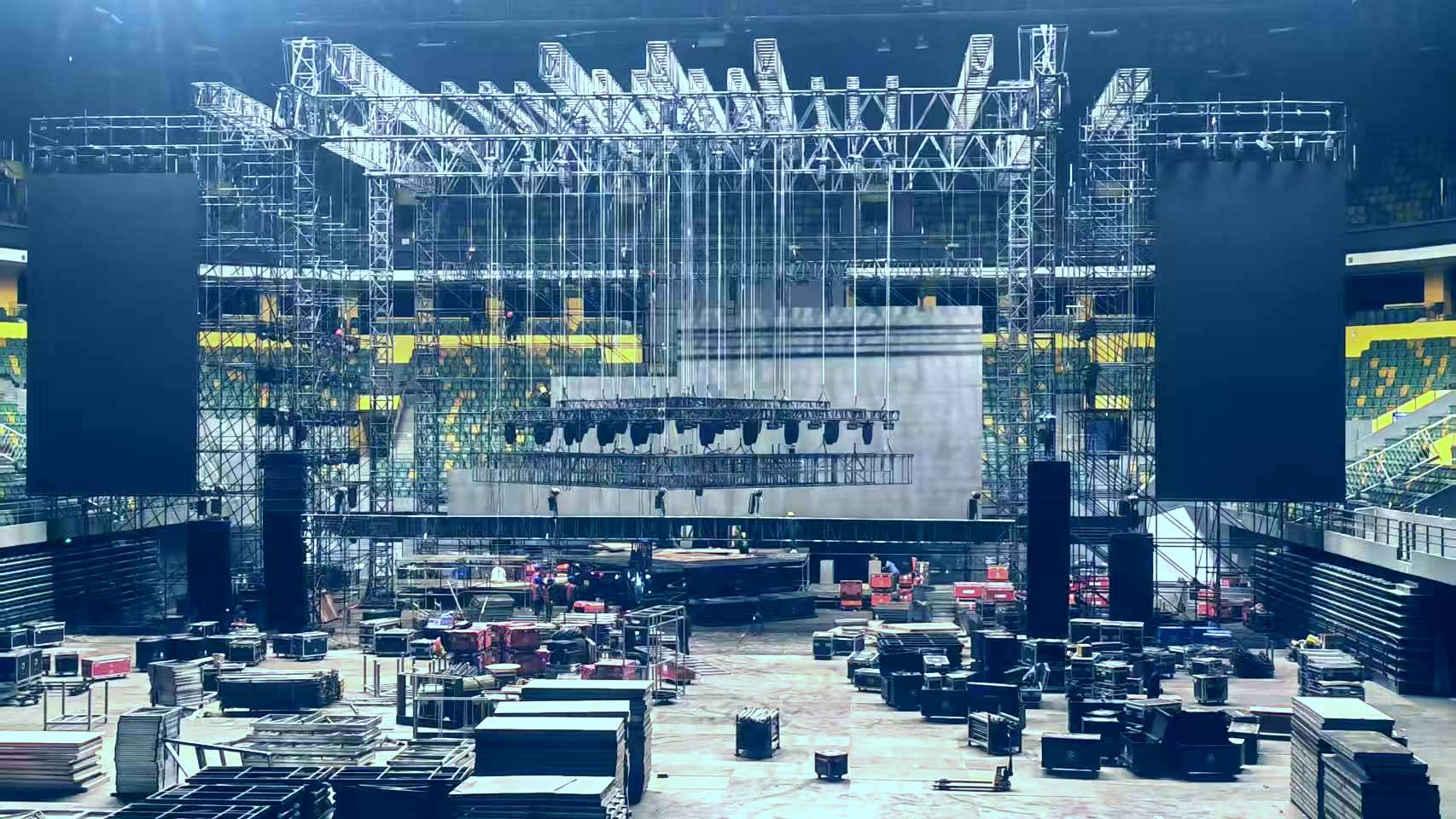

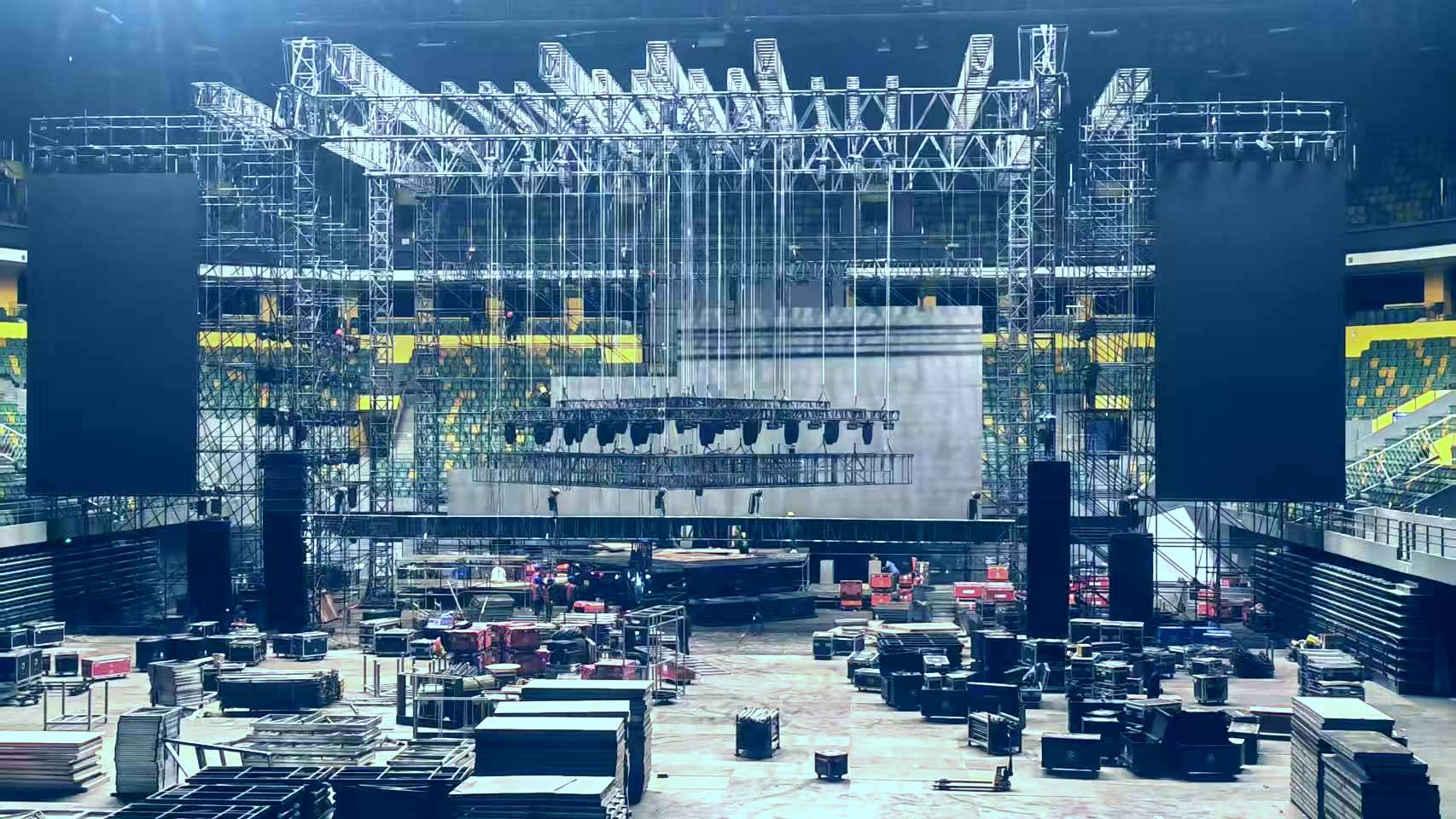

This article describes the installation process of an indoor pop concert stage at a venue in Zhengzhou City, Henan Province.

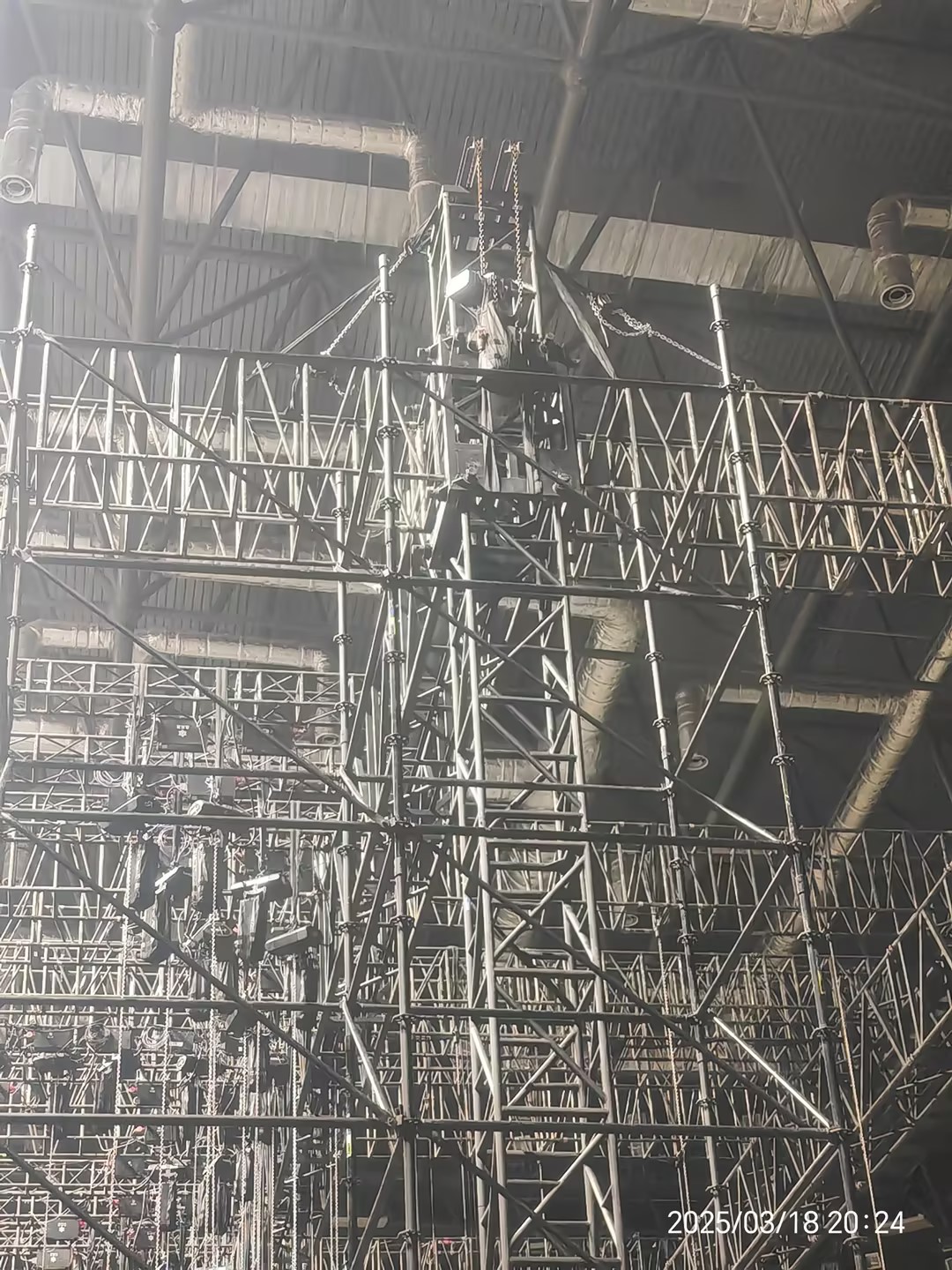

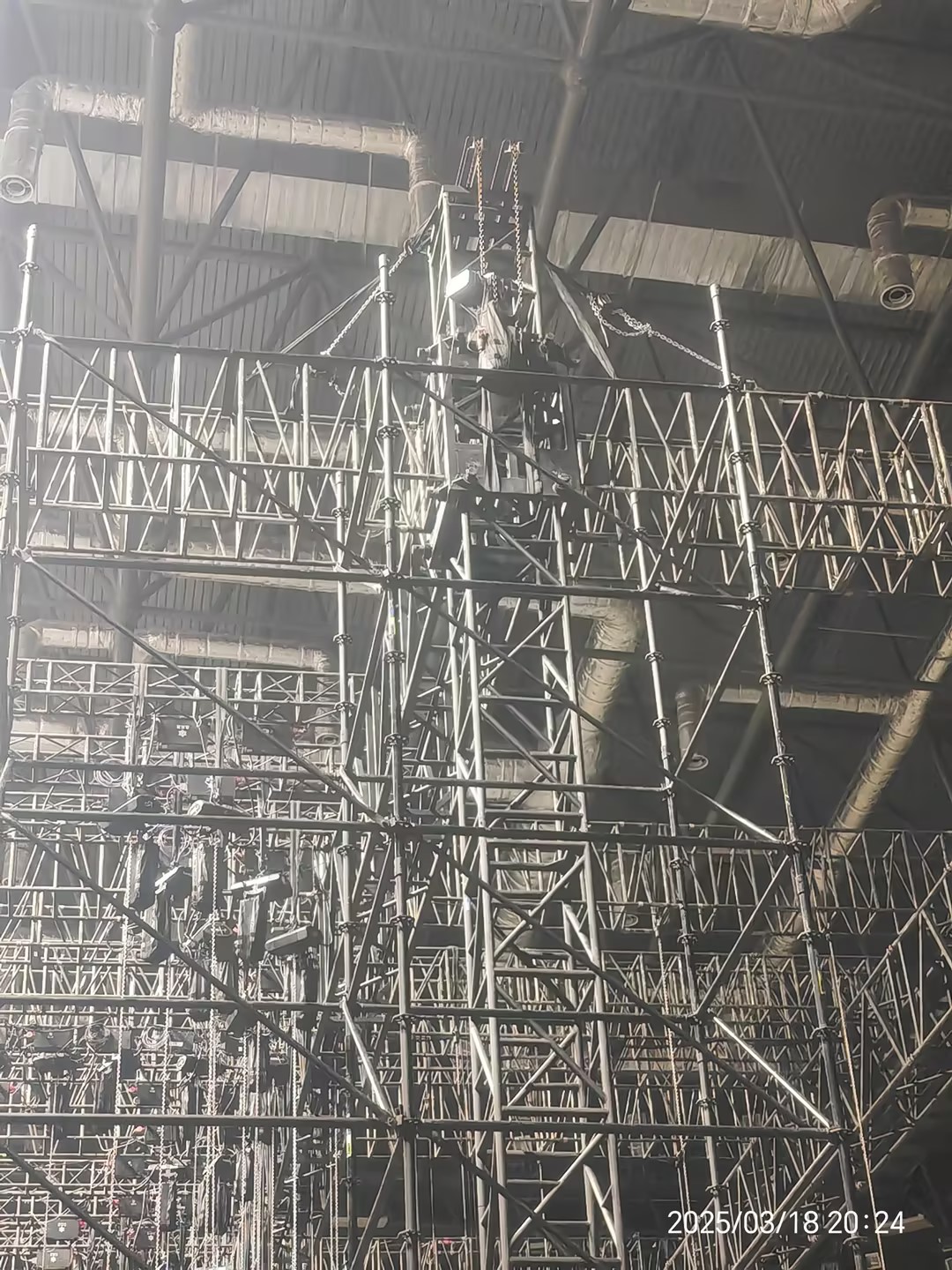

The stage’s overall design features an aluminum lighting truss system. It incorporates three - sided Layher LED trussing and a mechanical staging system.

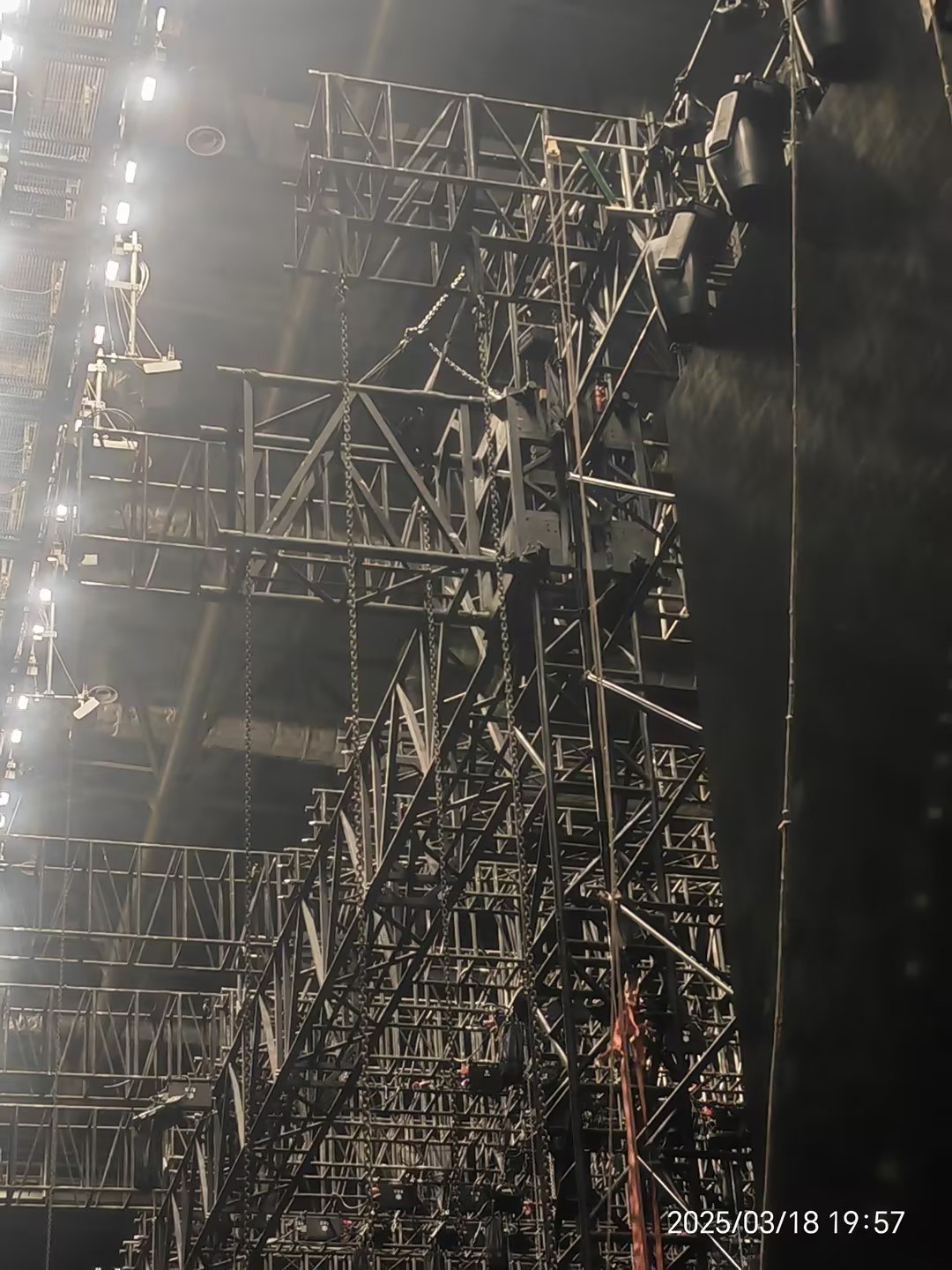

On the roof of the lighting truss, there are multiple groups of hoisting machines for lighting fixtures and LED screens. The main stage consists of several groups of motor - powered rising stages. The stage is surrounded by large LED displays on three sides, along with lighting and sound systems.

the main

truss system used steel base, steel sleeve block and aluminum truss. using forklift deliver pre-assemble truss for installation.

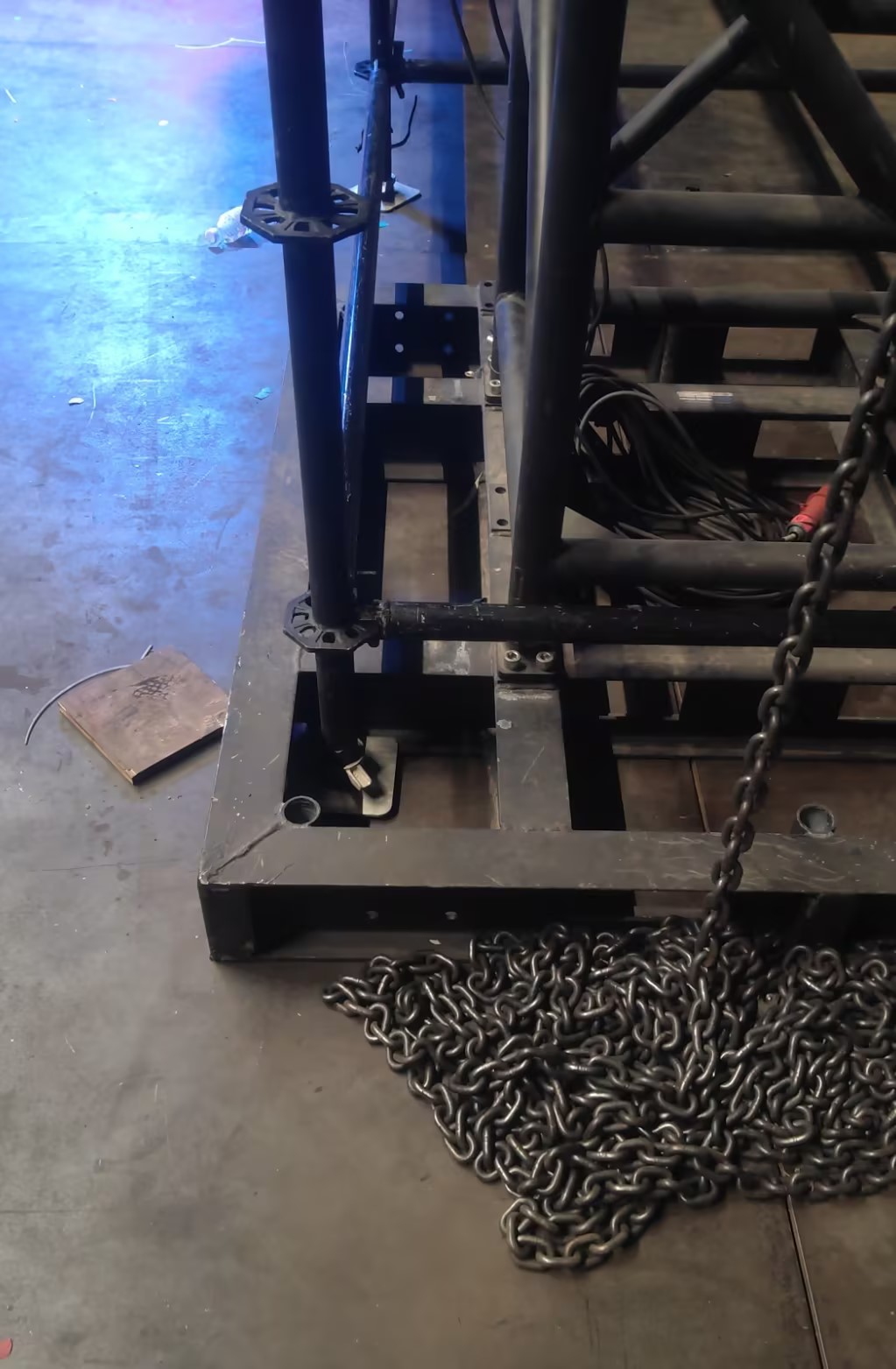

steel plate to level and protect the studium floor

forklift move the sleeve block and connect the beam truss

walkway big truss for concert

plastic band for marking and rolling move on the ground

slot helps welding firmly connecting tube to main tube

custom beam truss trolley help moving and connecting truss segments

multi use sleeve block for spigot truss and bolt truss

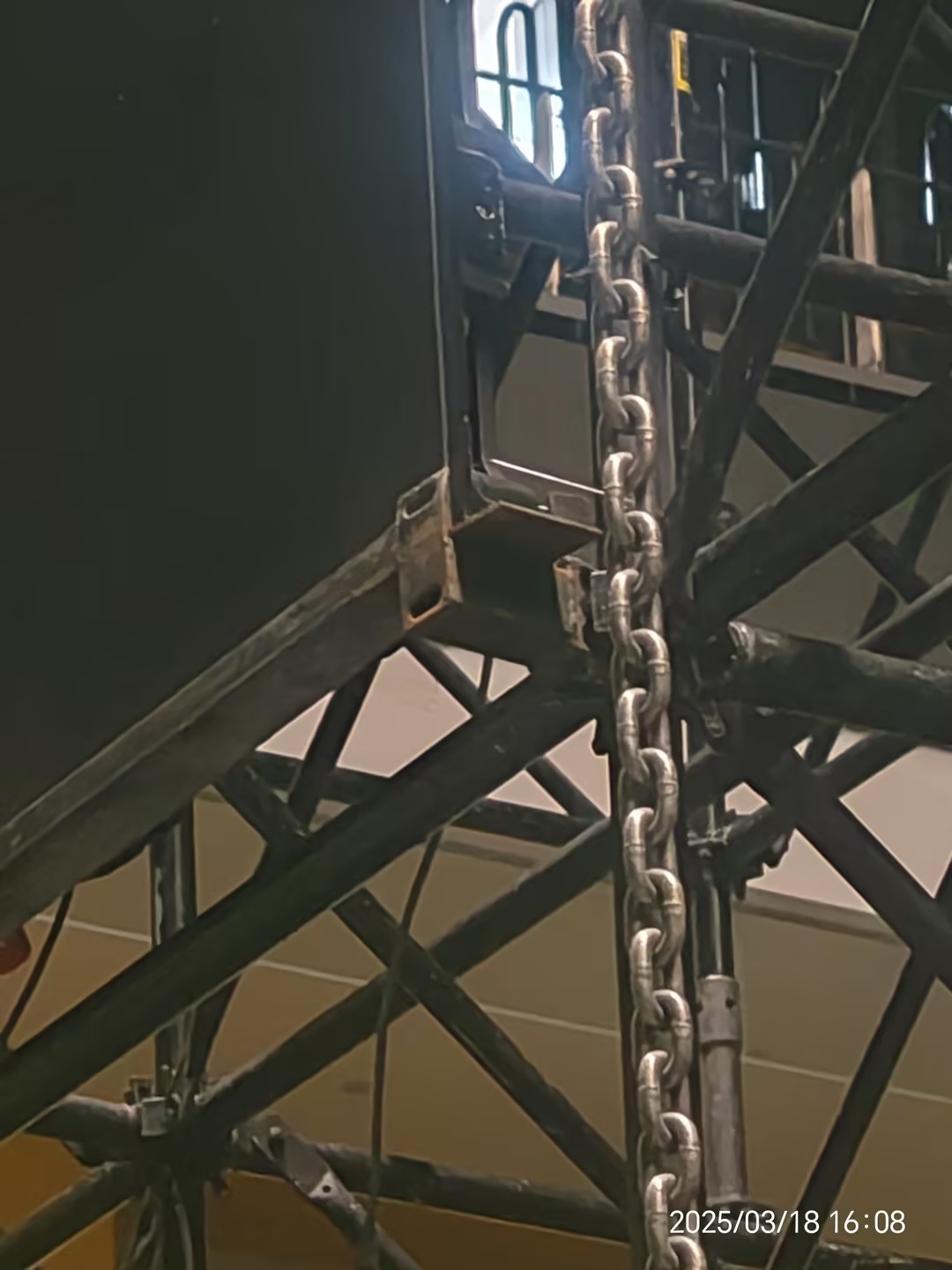

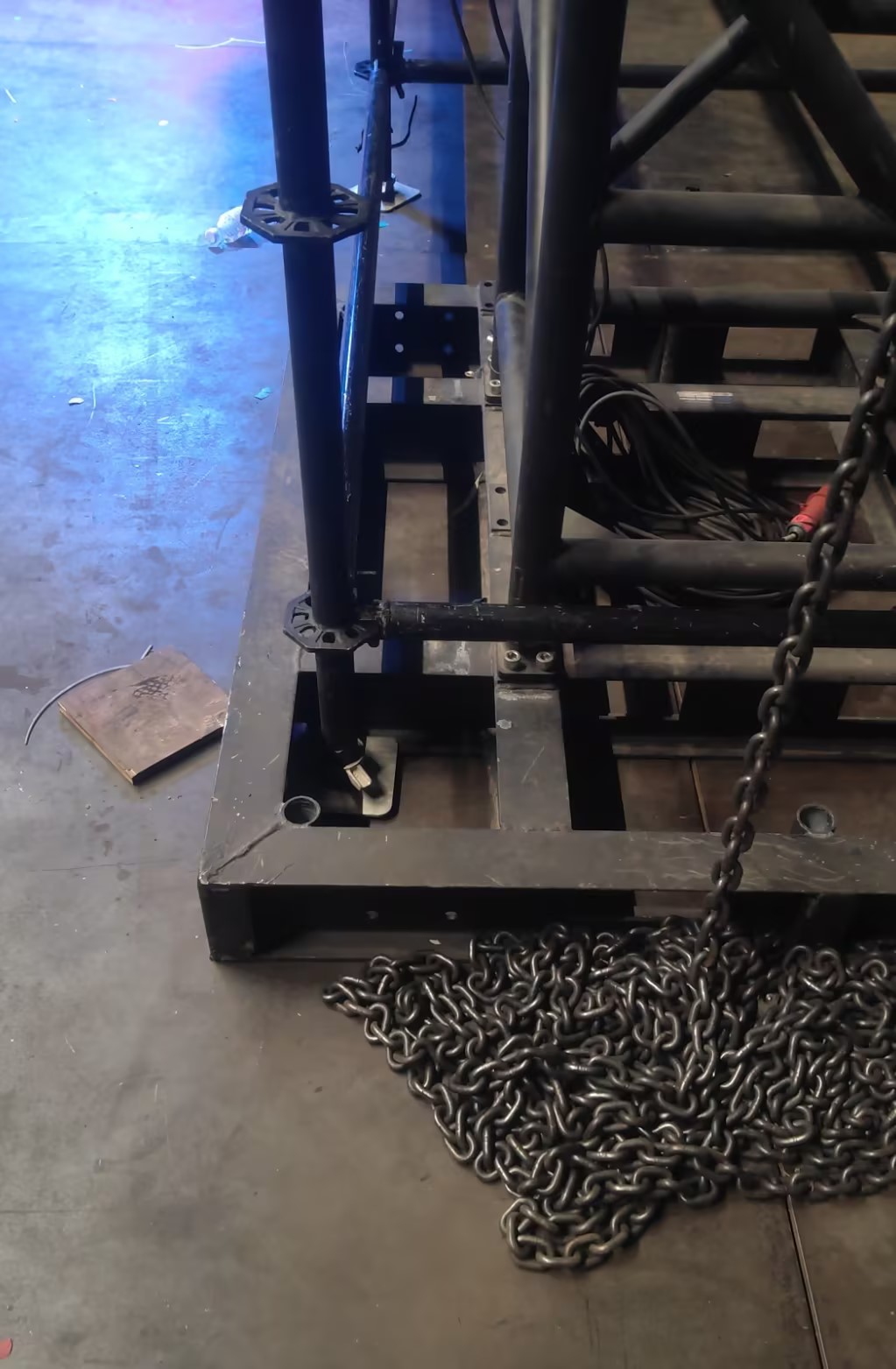

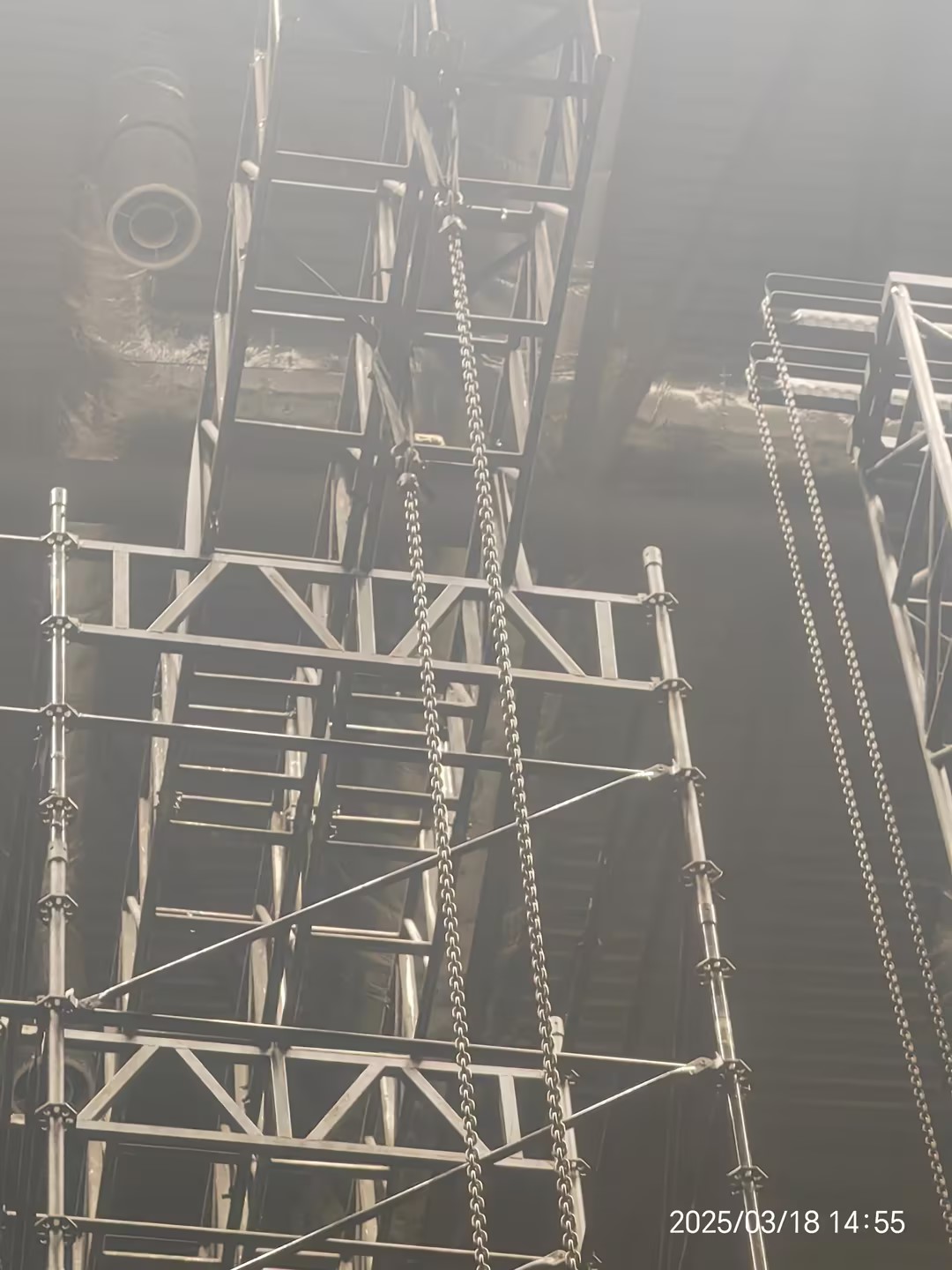

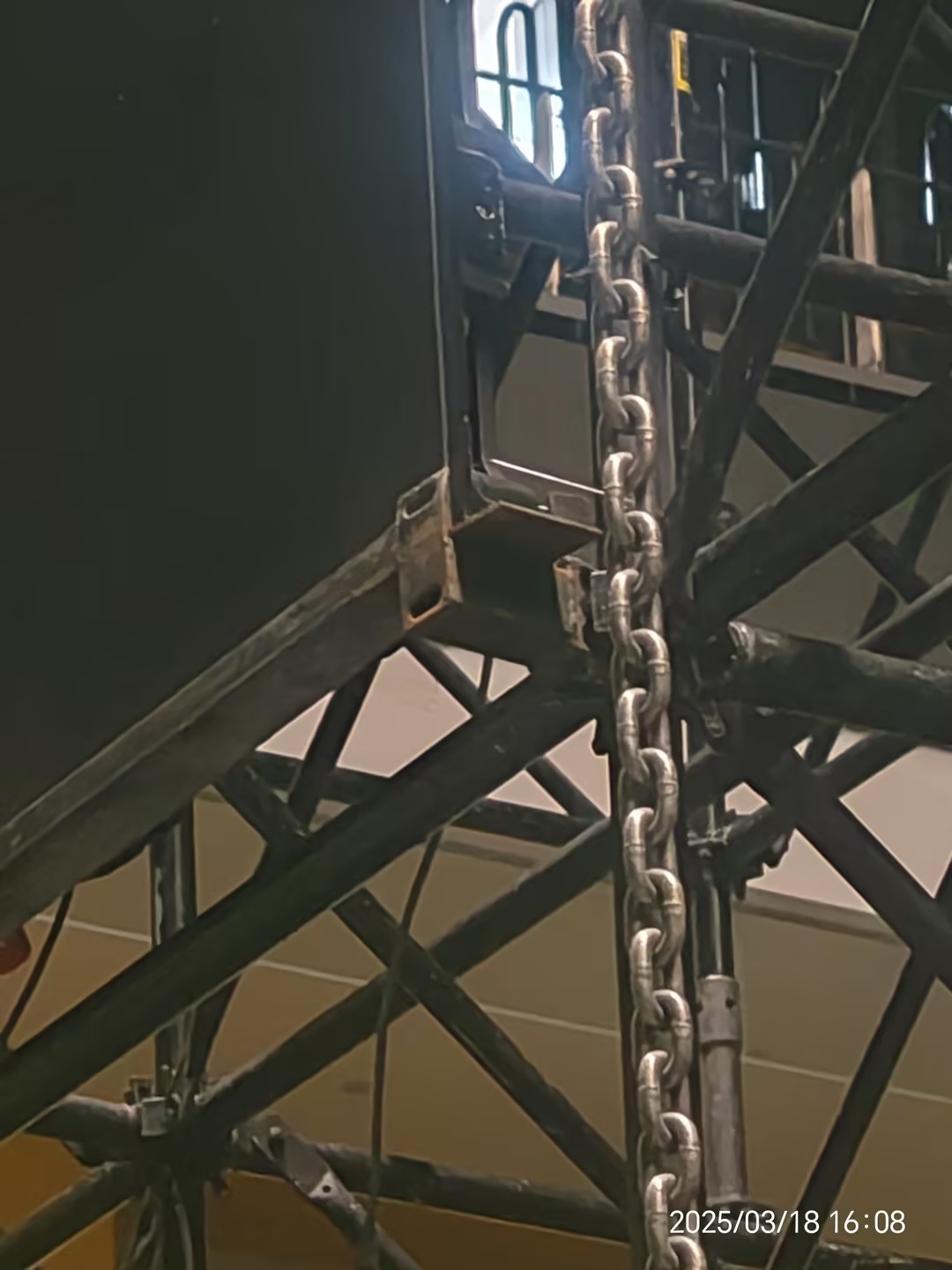

steel double top section for two pieces 2-tons motor

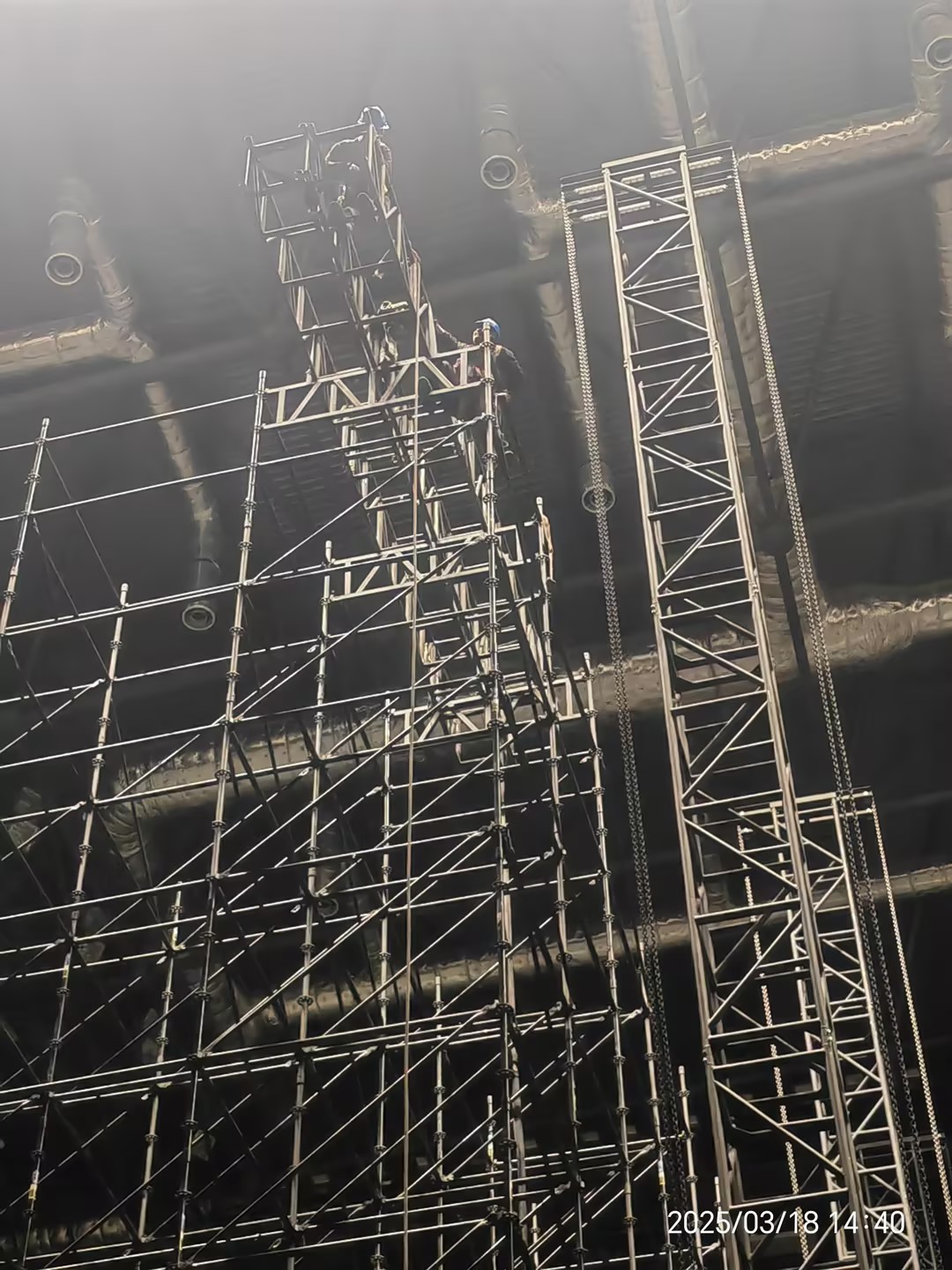

installation of double steel motor top section

steel truss erector helper for 20m piilar

Note that

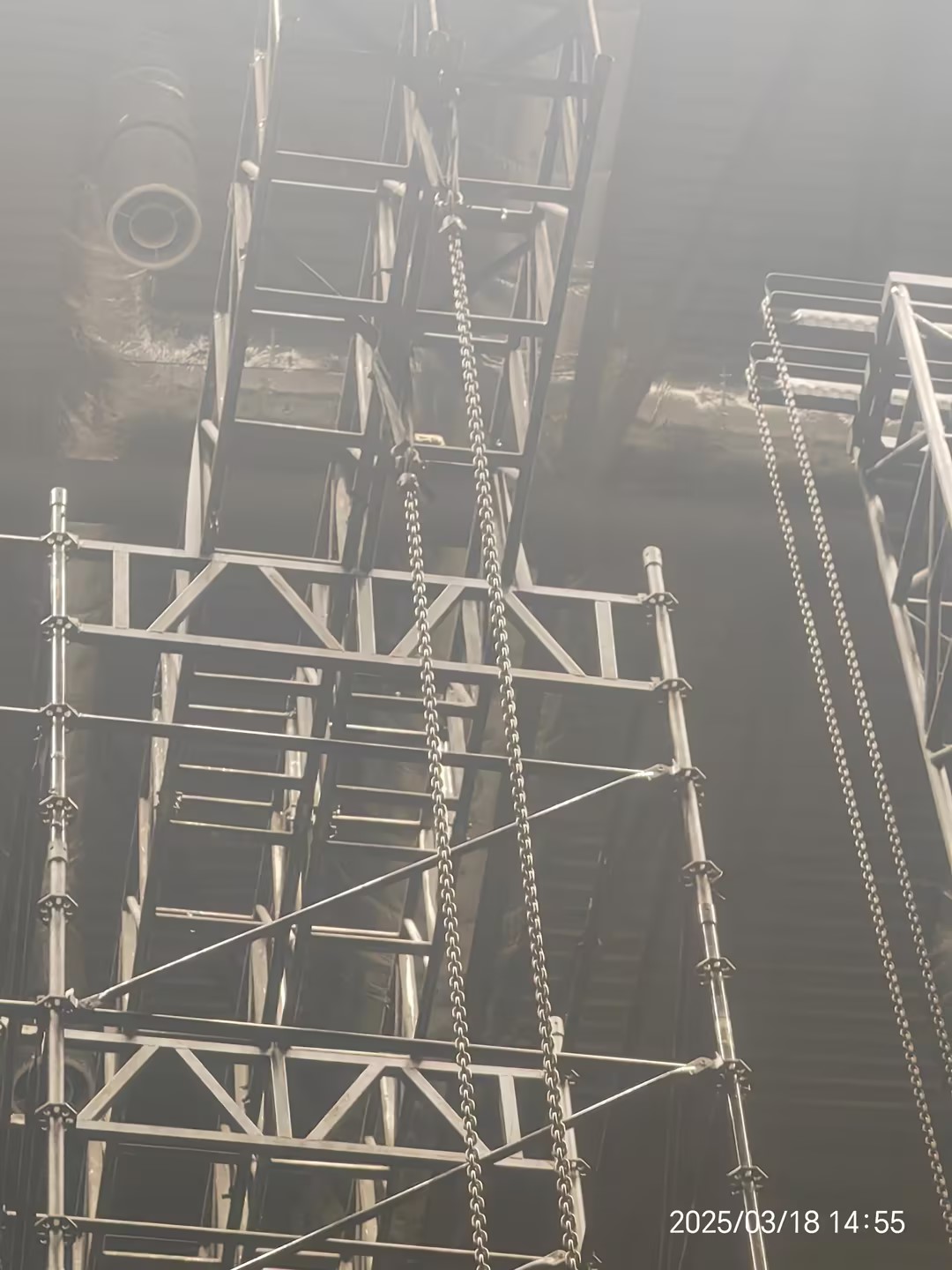

The wheel on the iron chain below should be large.

The auxiliary tower crane base should be connected to the column base, not just the handrail part

The vertical part of the auxiliary tower crane has a flexible connection base at the end, which facilitates vertical and storage

The 18 column (the part that needs to be erected simply) must be erected with an iron auxiliary tower crane. if it is to use aluminum alloy, it shall bent all at once.

put hook on the pillar about 16m high from the ground

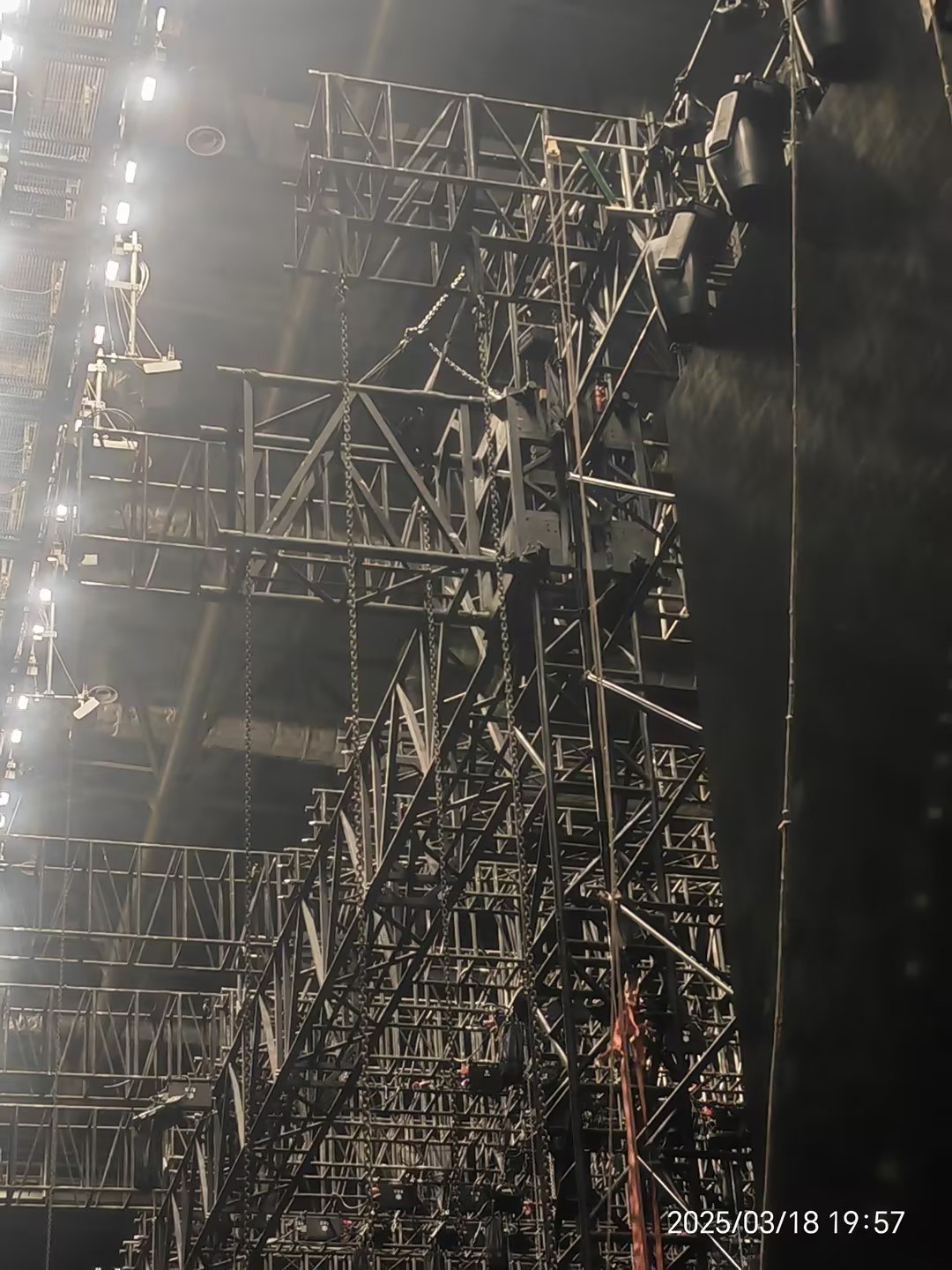

erecting 20m pillar truss with motor auxilary tower

lowering the erecting tower hook by rope

The installed auxiliary tower crane, with wheels, is very easy to move and perfectly fits with the column sleeve, increasing speed.

custom Simple trolley for transporting large trusses

custom Simple trolley for transporting large trusses

erecting 20m pillar truss by steel auxiliary truss helper

There are two key points to erecting a large truss.

Firstly, before pulling it up, the gourd chain should be straightened first.

Secondly, starting from the lifting, the hoist cannot stop until it stands upright, and the electric hoist should run for an additional two seconds.

moving the big truss pillar with forklifter

If there is mechanical handling, after the cross arm is installed on the ground, it can be directly moved to the designated location.

concert roof truss on the grid top with safety belt fixation

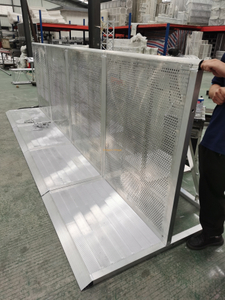

aluminum led display hanging truss frame, the most prominent feature is there is a base sheet on the bottom to hold and straighen the led bottom line.

black paint hexagonal disc layher truss can prevent rolling

inside and outside hoisting motors for pillar truss using in heavy duty trussing system

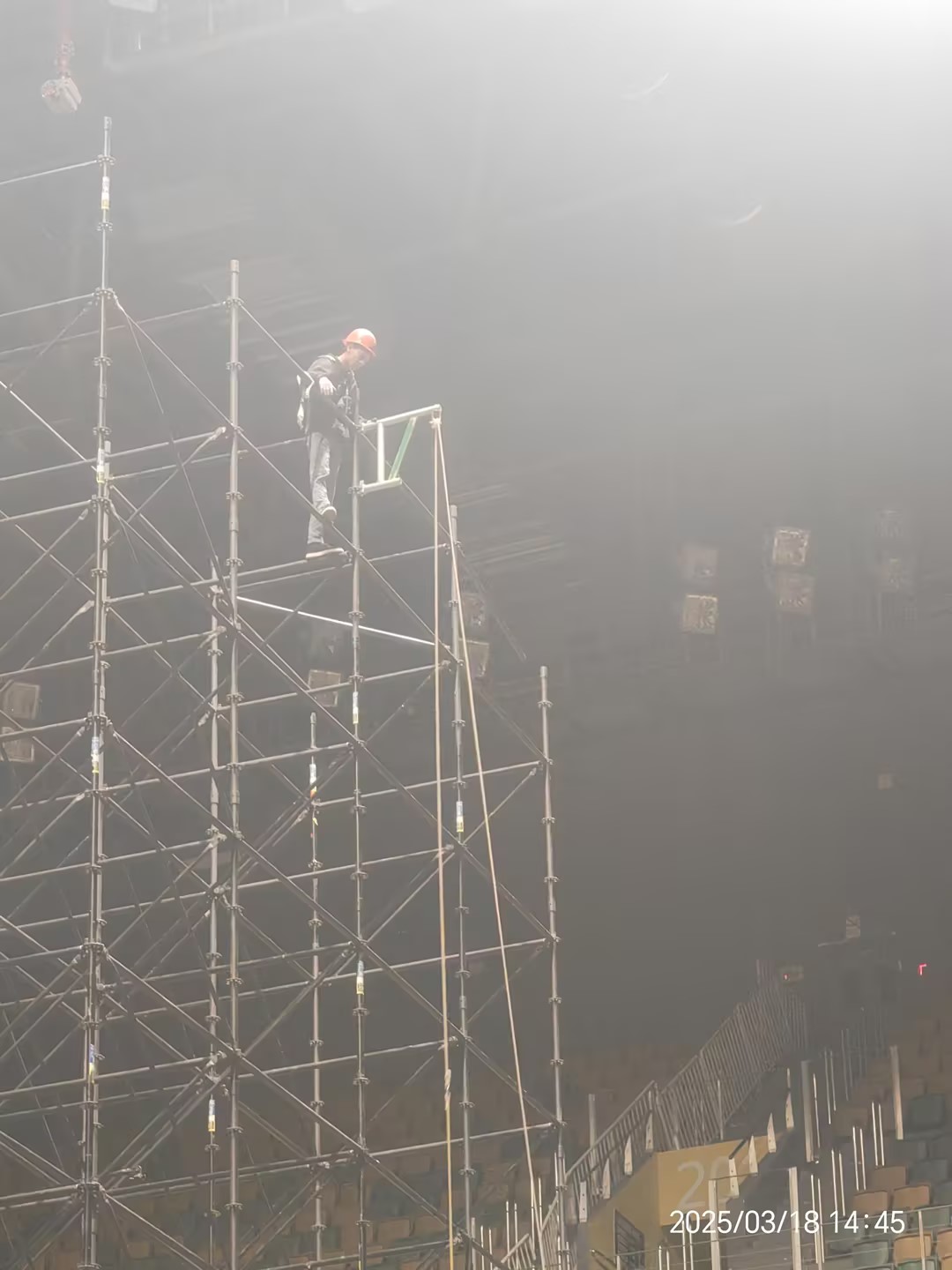

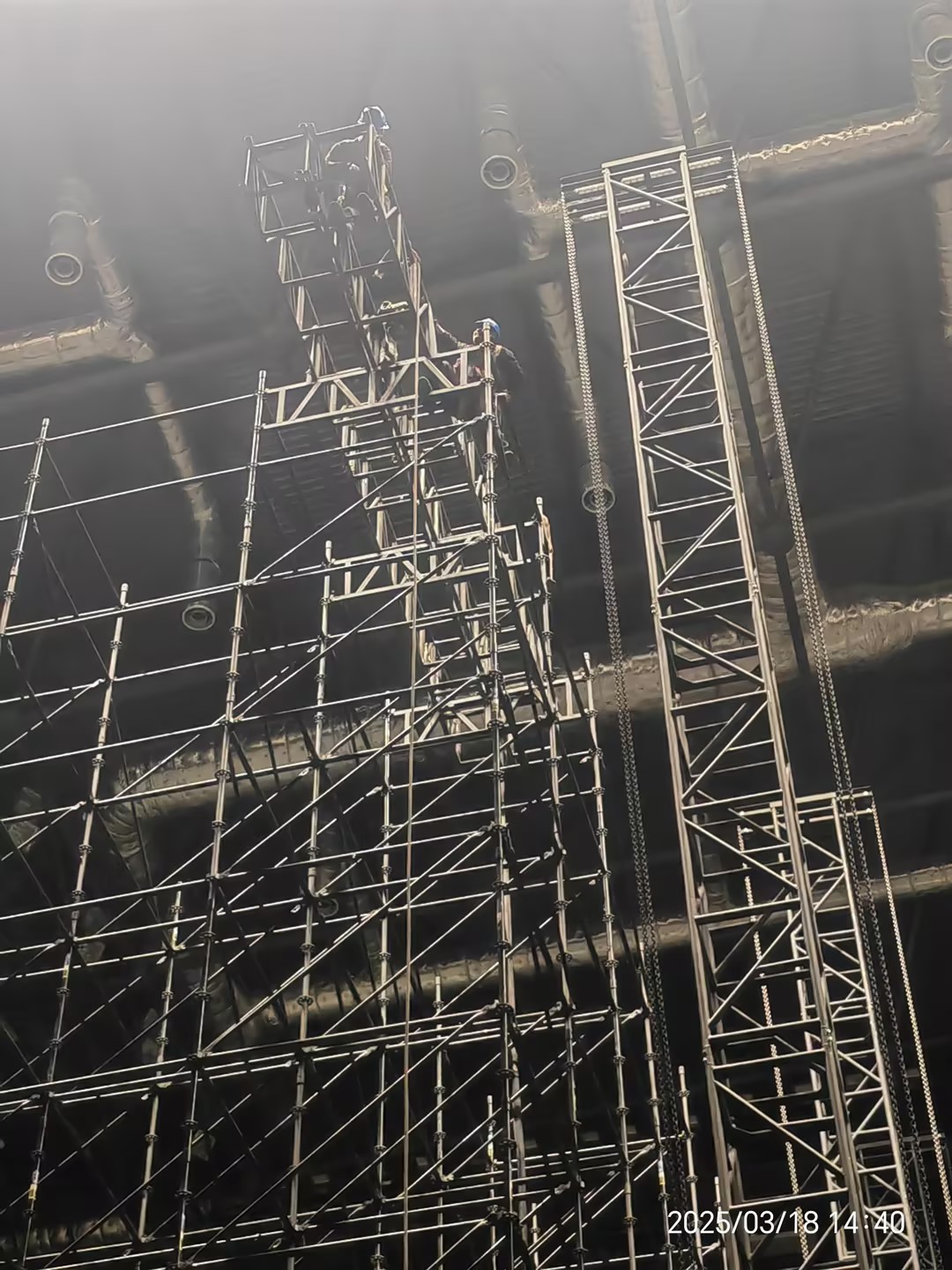

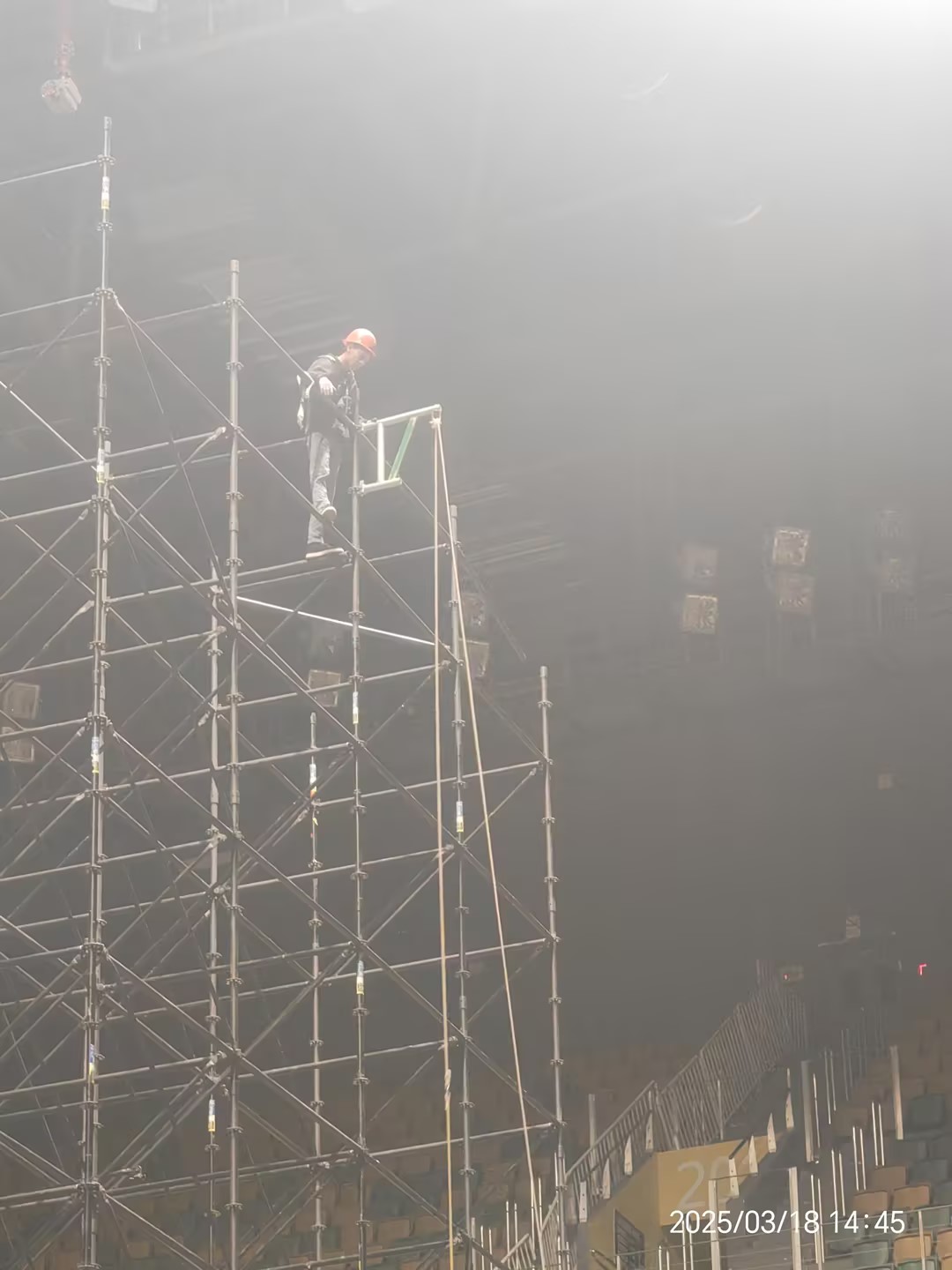

8 workers set up the scaffolding at a speed of 6 grids on the ground, 16 meters high, and takes approximately 60 minutes

There are two groups of layher scaffolding workers on site, each consisting of eight people.

to use two pieces of aluminum truss on the top together to hang sound system

led hoisting and installing on layher truss system

hoisting bracket for materials delivery

way of tieing safety belt and with motor hoists.

The lifted truss is first assembled outside the site, and the lighting is installed. Then, after the main truss is lifted, it is pulled up with a hoist.

when two eletrical hoists are used for lifting the trussing system, usually it should be arranged inside and outside

steel mobile storage cart for concerts

install all roofing equipments and cables before roof truss lifted

connect the power cable and signal wire before lifting the truss and lighting

led bracket support

how led wall bracket works in layher truss system

All hoist points are in place and the signal has been tested and passed before lifted

install the hoisting led frames for the indoor concert

The hanging lights are made of aluminum frames, while the hanging LED displays are made of iron frames

how to secure the prominent truss outside

Measures have been taken to prevent chain slippage.

To prevent the sound crossbeam from being pulled down, there is an safety strap at the back that is tightened with a small chain hoist.

Assemble the LED display screen and lock the pillars with wire every meter.

The horizontal bar is not locked.

The iron base should have holes left for future construction of the layher frame truss

Three wire trunking is the most commonly used

For the best sound effect, the linear array is curved and fixed with safety straps

Fixation and method of pull-down

At the forefront of the stage, the light frame should be concealed inside the gourd truss to maintain its aesthetic appeal

custom Simple trolley for transporting large trusses

custom Simple trolley for transporting large trusses