It provides a safe and stable platform for performers and equipment while allowing for creative lighting and audio setups. Here are some key components and considerations in designing an outdoor event stage truss system:

Truss Structures: Trusses are the primary components of the stage design system. They are usually made of aluminum or steel and consist of interconnected bars or tubes. Trusses provide the framework for supporting the stage, lighting fixtures, speakers, video screens, and other equipment.

Stage Platform: The stage platform is the raised area where performers and presenters stand. It is typically constructed using sturdy materials like plywood or aluminum and should be designed to handle the weight of performers, instruments, and props. The platform should also incorporate safety features like guardrails and non-slip surfaces.

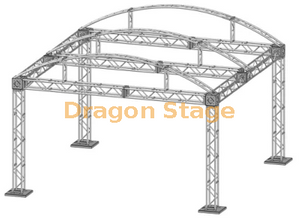

Roof Truss System: Outdoor stages often require a roof truss system to protect performers and equipment from weather conditions such as rain and sun. The roof truss provides overhead support and can be designed in various configurations, such as flat roofs, peaked roofs, or arched roofs. It should be engineered to withstand wind loads and be properly anchored to ensure stability.

Rigging Points: Rigging points are attachment points located on the truss structure from which lighting fixtures, speakers, and other equipment are hung. These points should be strategically placed and engineered to bear the weight of the equipment and to ensure proper distribution for balanced rigging.

Safety Considerations: Safety is of utmost importance when designing an outdoor event stage truss system. The design should comply with local regulations and industry safety standards. Adequate load calculations should be performed to ensure that the truss system can safely support the weight of all equipment, including dynamic loads caused by performers and equipment movements. Fall protection measures, such as safety cables, should be used to secure equipment to the truss system.

Accessibility and Egress: The stage truss design should consider accessibility for performers, crew members, and emergency personnel. Safe access routes, stairways, and ramps should be incorporated into the design. Emergency exits and evacuation plans should also be considered.

Professional Engineering and Rigging: It is crucial to involve professional engineers and rigging experts in the design process. They can assess the structural integrity, calculate load capacities, and provide guidance on proper installation and rigging techniques to ensure a safe and successful event.

When designing an outdoor event stage truss system, it is essential to work closely with experienced event production companies or staging specialists who can provide expertise in designing, assembling, and operating such systems to create a memorable and safe event experience.

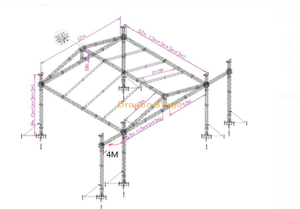

Integrated 9x8x5m Outdoor Event Stage Truss System: Heavy-Duty Aluminum Rigging

1. Introduction: The Need for Certified Outdoor Stage Truss Design

Executing a successful outdoor event, concert, or festival hinges on a robust and compliant support structure. A reliable outdoor event stage truss system must provide not only the necessary space but also the certified load-bearing capacity for professional-grade lighting, sound, and roof protection. The DragonStage 9m (W) x 8m (D) x 5m (H) truss design system is engineered specifically for this demanding environment.

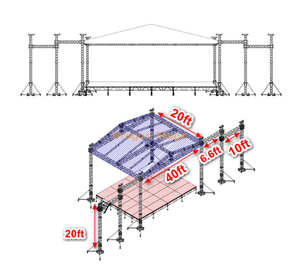

This integrated system offers event contractors and production managers a high-strength aluminum framework, complete with a stable 8x7m stage platform. It represents a fully modular and safety-focused solution for complex outdoor productions, guaranteeing maximum rigging potential and structural integrity against environmental elements.

2. Industry Challenges in Outdoor Rigging and Structural Solutions

Outdoor staging presents unique challenges, primarily related to wind loading, variable ground conditions, and the need for rapid, safe assembly of heavy technical equipment. Failure to adhere to rigorous safety standards, particularly concerning overhead rigging, poses significant legal and operational risks to event organizers.

DragonStage provides a precision-engineered solution by coupling a comprehensive heavy-duty aluminum truss structure with a stable modular stage platform. The system uses robust CS289x289 square truss components with a main tube size of $50 \times 3.0$mm, ensuring the required strength-to-weight ratio for safe heavy lifting (Source:https://en.wikipedia.org/wiki/Truss). This adherence to professional specifications and technical precision addresses the critical pain points of certified load management and structural resilience, essential components of a compliant outdoor structure.

3. Key Features for Professional Load Management and Safety

This fully integrated outdoor event stage truss design system is defined by components engineered for both high performance and installer efficiency, significantly enhancing safety and operational flexibility.

Integrated Ground Support and Stability

The 9x8x5m outdoor stage truss is supported by four robust pillar sets and specialized base components, including four Steel Base S elements and Long Outriggers (16 pieces). This ground support infrastructure is vital for dispersing the system’s weight and ballast requirements, ensuring stability against lateral forces common in open-air venues. Rigging is simplified through the inclusion of four 2-Ton Manual Hoists (BA05) and associated rigging gear, facilitating safe and controlled vertical deployment of the roof and lighting elements.

Dedicated Roof Structure for Weather Protection

A critical feature of any outdoor system is the protection of expensive equipment and performers. This design includes a dedicated roof structure, featuring specific corner pieces and a PVC canopy material in blue (or customized color). The roof assembly utilizes specialized components like Roof Corners (4 ways) and an 8.00m Top Beam set, ensuring water runoff and providing a resilient shield against solar exposure and rain.

Comprehensive Staging Platform Integration

The structure is seamlessly paired with an 8x7m stage platform, constructed from 28 pieces of 1x2m wooden topping modules. This platform includes 40 stands with adjustable bases and two 5-step stage stairs with a height range of 0.8-1.2m, providing safe, regulated access for performers and crew, and ensuring the final structure is ready to host a full-scale event (Source:https://www.dragontruss.com/Stage-Truss-System.html).

4. Practical FAQ for Production Managers

| Question | Answer |

| Q: What is the primary truss size used? | The system utilizes CS289x289 square truss with a $50 \times 3.0$mm main tube, chosen for its optimal load-bearing capabilities in large-span outdoor applications. |

| Q: Is this system provided with lifting equipment? | Yes, the package includes four 2-Ton Manual Hoists (BA05) and Fibre Slings (BA04), providing the essential tools for safe vertical rigging and setup. |

| Q: How large is the total stage area? | The truss structure provides a total footprint of $9m \times 8m \times 5m$, enclosing an 8m x 7m modular stage platform that is suitable for mid-to-large-scale performances. |

| Q: Does the system include rigging points for lighting and audio? | Yes, the truss structure itself serves as the designated rigging points, engineered with sufficient structural redundancy to safely bear the weight of lighting fixtures, line arrays, and video screens. |

5. Strong Call to Action (CTA)

Don't gamble on outdoor structural integrity. Rely on a TUV-certified design built for heavy-duty performance and unparalleled safety.

Contact DragonStage's structural engineering team today to review the load calculations and secure this 9x8x5m professional outdoor stage truss system for your next major event.