packing volume: 33cbm

packing weight: 3650kg

| Item |

| Specification(squre truss) | Qty |

| length | main tube(mm) | size(mm) |

| 18.00 m Beam(front) | 3 sets | 3.00 m | 50×3.0 | CS500×600 | 18pcs |

| 2.00 m | 50×3.0 | CS500×600 | 0pcs |

| 1.00 m | 50×3.0 | CS500×600 | 0pcs |

| 15.00 m Beam(side) | 2 sets | 3.00 m | 50×3.0 | CS500×600 | 10pcs |

| 2.00 m | 50×3.0 | CS500×600 | 0pcs |

| 1.00 m | 50×3.0 | CS500×600 | 0pcs |

| 9.00 m Pillar | 6 sets | 3.00 m | 50x3.0 | CS350×350 | 18pcs |

| 2.00 m | 50x3.0 | CS350×350 | 0pcs |

| 1.00 m | 50x3.0 | CS350×350 | 0pcs |

| Frame Tower | Spigot Sleeve Block M | 6pcs |

| Steel Base M | 6pcs |

| Top Section M | 6pcs |

| Manual hoist,BA05 2Tons | 6pcs |

| Spigot Hinge Section,Height 1m | 6pcs |

| Fibre sling,BA04,2 tons 3m | 6pcs |

| Long outrigger | 24pcs |

| Item |

| Specification(squre truss) | Qty |

| length | main tube(mm) | size(mm) |

| Roof Pillar | 3 sets | 1.80 m | 50×3.0 | CS289×289 | 3pcs |

| 15.00 m Top Beam | 1 sets | 3.00 m | 50×3.0 | CS289×289 | 5pcs |

| 2.00 m | 50×3.0 | CS289×289 | 0pcs |

| 1.00 m | 50×3.0 | CS289×289 | 0pcs |

| 9.20 m Oblique Beam | 6 sets | 3.00 m | 50×3.0 | CS289×289 | 12pcs |

| 2.00 m | 50×3.0 | CS289×289 | 6pcs |

| 1.20 m | 50×3.0 | CS289×289 | 6pcs |

| 9.20 m Ladder truss | 12 sets | 3.00 m | 50×3.0 | CL30,289*50 | 24pcs |

| 2.00 m | 50×3.0 | CL30,289*50 | 12pcs |

| 1.20 m | 50×3.0 | CL30,289*50 | 12pcs |

| Roof Components |

| roof conner 4 ways, use for roof beam truss | CS289×289 | 2pcs |

| roof conner 5 ways, use for roof beam truss | CS289×289 | 1pcs |

| Connect plate with clamp | 3pcs |

| Single clamp | 24pcs |

| Double clamp | 12pcs |

| roof canopy material:pvc, Blue Colour or customized. | 412.56 | 1pcs |

packing volume: 30cbm

packing weight: 4600kg

| Aluminium assembly stage | topping: 4x8ft

(1.22x2.44m) | wooden | 77 pcs |

| 1.22m stage brace | 88 pcs |

| 2.44m stage brace | 84 pcs |

| stand with extendable tube | 96 pcs |

| Stage adjustable base | 96 pcs |

| Stage Stair | wooden topping | total | 8 | steps | 2 pcs |

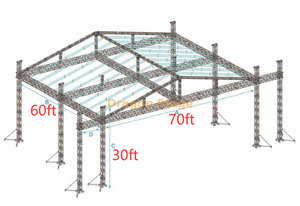

Aluminum Event A-Roof Truss System: Large-Scale Truss Rooftop for Sale 18x15x10m

1. Introduction: The Foundation of Large-Scale Live Production

The DragonStage Aluminum Event A-Roof Truss System is an exceptionally large, heavy-duty ground support structure engineered for the most demanding outdoor events, including major music festivals, large sporting ceremonies, and comprehensive corporate installations. Sized at an impressive 18 meters wide by 15 meters deep with a striking 10-meter clear height, this system offers maximum coverage and vertical clearance for complex lighting, sound, and video rigging plots.

This large-scale truss rooftop for sale is categorized as an A-frame Roof Truss System, a design renowned for its superior load distribution and stability in adverse weather conditions. The structure achieves its robustness by utilizing two distinct, heavy-duty profiles: CS500x600 Truss for the main roof beams (providing maximum span capability) and CS350x350 Truss for the supporting pillars. This strategic material deployment ensures a reliable and certified platform for any ambitious production design.

2. Challenges & Solutions in Modern Event Construction

Producing major events requires overcoming critical challenges related to structural stability, load management across long spans, and managing vast logistical footprints. This system is designed to address these professional needs:

Handling Extreme Spans and Loads: To safely cover an 18m x15m area, the roof grid must handle high loads over significant distances. By specifying the CS500x600 Heavy Duty Truss for the main horizontal runs, DragonStage provides the necessary engineering resilience, minimizing deflection while maximizing usable rigging weight capacity.

Safety in Elevation and Stability: Erecting a structure with a 10m height requires enhanced safety features. This system uses 6 primary pillars equipped with robust Spigot Sleeve Block M components, reinforced by 24 Long Outriggers for increased resistance to overturning moments (Source:https://www.dragontruss.com/Typical-A-frame-Roof-Truss-System-pl3101260.html). Furthermore, all lifting operations utilize 2-Ton Manual Hoists (BA05) and Fibre Slings for safe, controlled deployment.

Integrated Production Space: The structure is packaged with a massive, dedicated modular stage platform sized approximately 13.42mx17m (Stage platform: 13.42m $\times$ 17m, height 1.2-2m). This pre-calculated stage footprint eliminates interface issues between stage and structure, ensuring a perfect fit and faster build time on site. As a key principle in staging, proper integration between the stage and truss structure is fundamental to safety (Source:https://en.wikipedia.org/wiki/Stage).

3. Key Features & Benefits for Event Professionals

The Aluminum Event A-Roof Truss System 18x15x10m offers technical specifications optimized for maximum performance and logistical efficiency.

| Feature | Specification Details | Client Benefit |

| Overall Dimensions (L x W x H) | 18m x 15m x 10m (Rooftop) | Provides one of the largest certified covered spaces available, ideal for main stages and large crowds. |

| Main Roof Truss Profile | CS500x600 (Square Spigot Truss) | Ensures superior load-bearing capacity across the long 18m span for heavy lighting and video walls. |

| Pillar Truss Profile | CS350x350 (Square Spigot Truss) | Offers a strong yet manageable support column profile, utilizing 6 pillars for enhanced stability. |

| Stage Platform Size | $\approx 13.42\text{m} \times 17\text{m}$ (77 pieces of 4x8ft topping) | Provides an enormous, adjustable performance area, significantly reducing setup time for the overall event space. |

| Roof Canopy Coverage | PVC material, 412.56 sqm | Offers comprehensive weather protection across the main rigging and stage area. |

| Truss Connection | Spigot (Conical Coupler, Safety Clip, and Pin) | Facilitates quick, secure, and reliable assembly of the heavy-duty components. |

The main structural components, including the CS500x600 beams and CS350x350 pillars, all feature a 50mmx3.0mm main tube size, a key indicator of the system's heavy-duty rating. Rigging hardware such as the Spigot Sleeve Block M, Steel Base M, and Top Section M are appropriately scaled for the size and height of the structure. The robust stage decking includes 77 wooden 4x8ft panels, supported by 96 sets of adjustable stands and bases, capable of setting the platform height between 1.2m and 2.0m. The modular nature of these components is crucial for rapid turnover in the touring market (Source:https://www.dragontruss.com/stage-products-list.html).

4. Practical FAQ for Stage Professionals

Q: What is the primary benefit of the A-Roof design over a Flat Roof for this size?

A: The A-Roof design, also known as a gabled roof, provides inherent structural integrity for large spans and assists with natural water runoff, which is critical for 412sqm of canopy area.

Q: Are the pillars capable of handling the side loads from video screens or sound wings?

A: Yes, the use of the CS350x350 profile, combined with the Long Outriggers and M-rated sleeve blocks, makes the 6-pillar structure suitable for handling significant lateral forces and distributed loads.

Q: What is the estimated total logistical volume for this entire system?

A: The total packing volume for the complete truss and stage system is 63 CBM (33 CBM truss, 30 CBM stage), simplifying freight and transportation planning.

Q: How is the stage height adjusted in the field?

A: The stage height from 1.2m to 2.0m is achieved through the included stand with extendable tubes and corresponding Stage adjustable bases, providing precise height leveling.

5. Strong Call to Action (CTA)

For the largest productions where performance, safety, and scale are paramount, choose the DragonStage Aluminum Event A-Roof Truss System 18x15x10m.

Contact DragonStage’s engineering team today to secure certified load data and customized production drawings for your next large-scale truss rooftop project.