For those seeking a more robust and visually striking truss system, our 18m wide aluminum truss kits provide an excellent alternative. In addition to their enhanced aesthetics, these aluminum truss systems offer superior load-bearing capabilities, enabling them to cover longer spans. To ensure stability and address deflection concerns in longer spans, our 18m wide stage truss is equipped with convenient spigot joints. These joints not only simplify the setup process but also provide added stability.

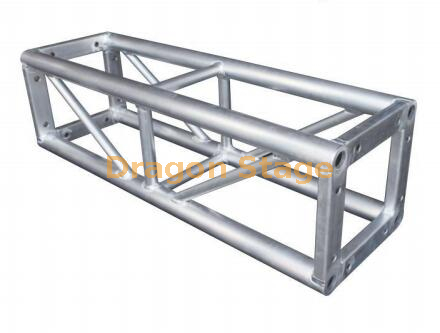

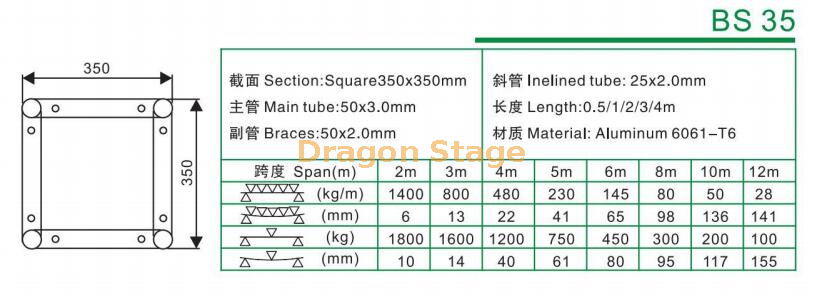

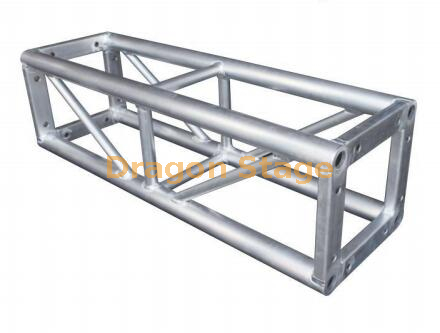

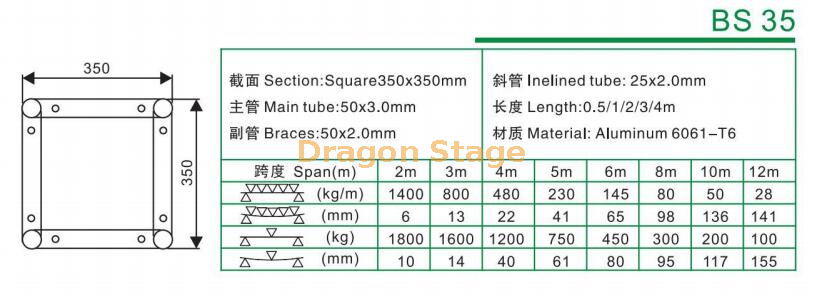

pillar truss 350x350mm

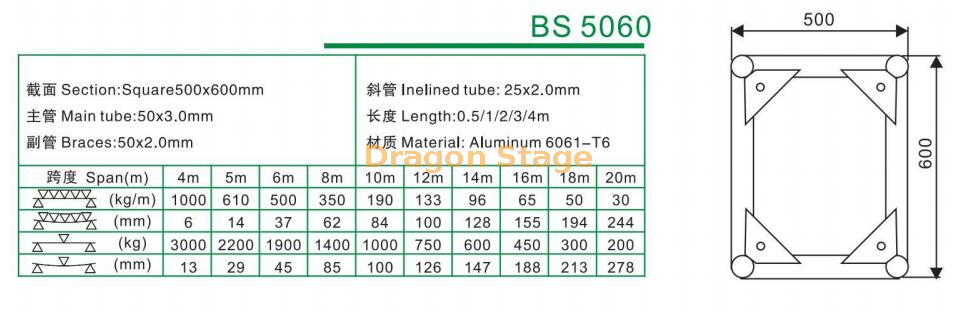

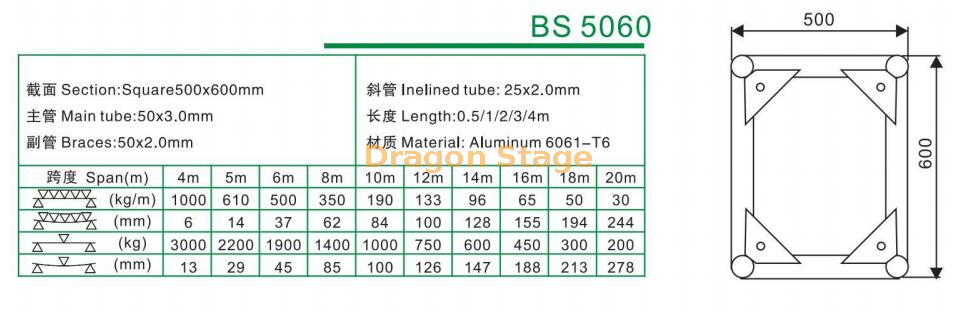

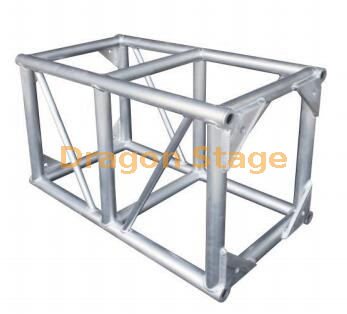

beam truss 500x600mm

canopy roof truss

breakdown

packing weight: 3400kg

packing volume: 30cbm

| Item |

| Specification(squre truss) | Qty |

| length | main tube(mm) | size(mm) |

| 18.00 m Beam(front) | 3 sets | 3.00 m | 50×3.0 | BS500×600 | 18pcs |

| 12.00 m Beam(side) | 2 sets | 3.00 m | 50×3.0 | BS500×600 | 8pcs |

| 9.00 m Pillar | 6 sets | 3.00 m | 50x3.0 | BS350×350 | 18pcs |

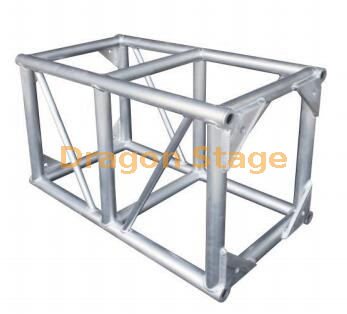

| beam cube | cube 500x600 | 1pcs |

| Frame Tower | Bolt Truss Sleeve Block M | 6pcs |

| Steel Base M | 6pcs |

| Top Section M | 6pcs |

| Manual hoist,BA05 2Tons | 6pcs |

| Spigot Hinge Section,Height 1m | 6pcs |

| Fibre sling,BA04,2 tons 3m | 6pcs |

| Long outrigger | 24pcs |

| Item |

| Specification(squre truss) | Qty |

| length | main tube(mm) | size(mm) |

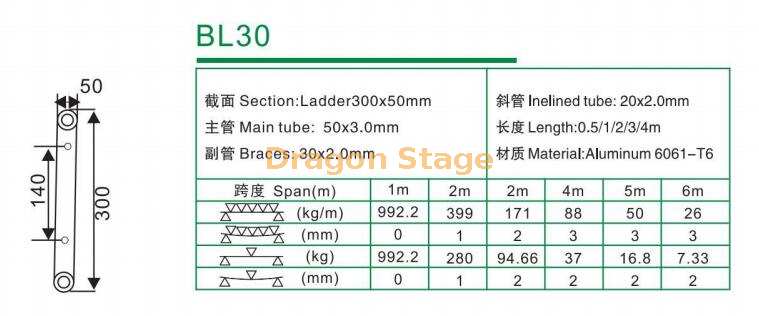

| Roof Pillar | 3 sets | 1.80 m | 50×3.0 | BS300×300 | 3pcs |

| 12.00 m Top Beam | 1 sets | 3.00 m | 50×3.0 | BS300×300 | 4pcs |

| 9.20 m Oblique Beam | 6 sets | 3.00 m | 50×3.0 | BS300×300 | 12pcs |

| 2.00 m | 50×3.0 | BS300×300 | 6pcs |

| 1.20 m | 50×3.0 | BS300×300 | 6pcs |

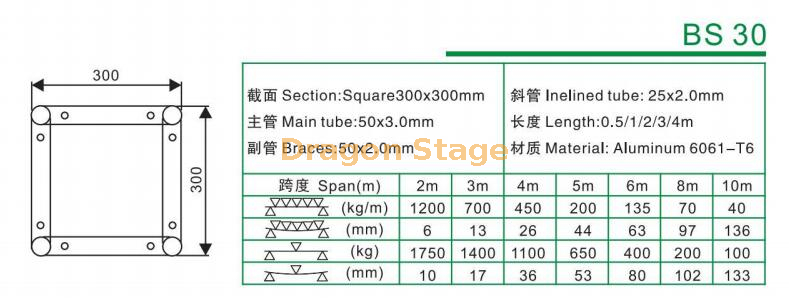

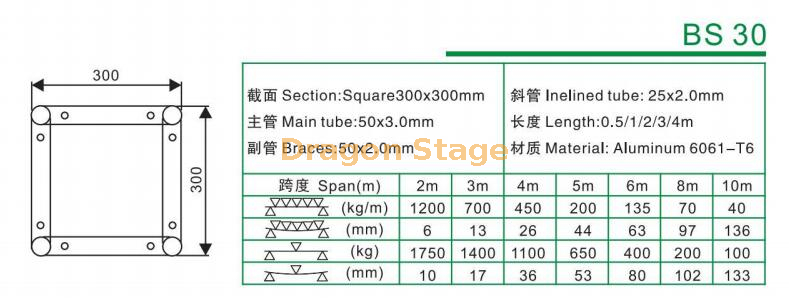

| 9.20 m Ladder truss | 8 sets | 3.00 m | 50×3.0 | BL30,300*50 | 16pcs |

| 2.00 m | 50×3.0 | BL30,300*50 | 8pcs |

| 1.20 m | 50×3.0 | BL30,300*50 | 8pcs |

| Roof Components |

| roof conner 4 ways, use for roof beam truss | BS300×300 | 2pcs |

| roof conner 5 ways, use for roof beam truss | BS300×300 | 1pcs |

| Connect plate with clamp | 3pcs |

| Single clamp | 16pcs |

| Double clamp | 12pcs |

| roof canopy material:pvc, Blue Colour or customized. | 350.16 | 1pcs |

packing weight: 5200kg

packing volume: 35cbm

| Item | Specification | Quantity |

| Aluminium assembly stage | topping:1x2m | wooden | 88 pcs |

| 1m stage brace | 99 pcs |

| 2m stage brace | 96 pcs |

| stand with extendable tube | 108 pcs |

| Stage adjustable base | 108 pcs |

| Stage Stair | wooden topping | total | 7 | steps | 2 pcs |

| Stair handrail | length | 3.18 | meters | 4 pcs |

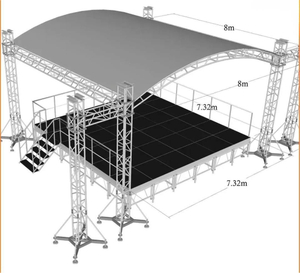

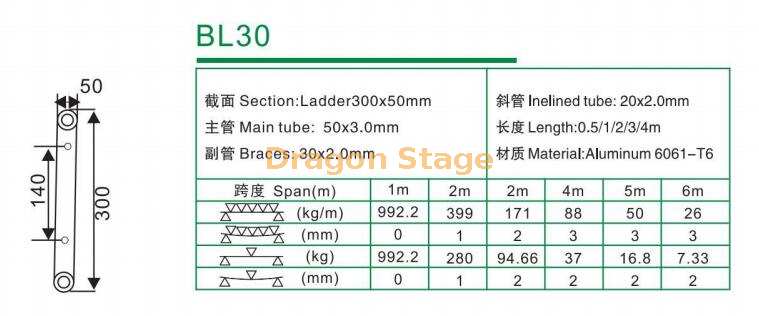

Aluminum Roof Stage Truss for Stage Lighting Rigging and Concert Events 18x12x10m: Heavy-Duty Bolt System

1. Introduction: The Foundation of Large-Scale Live Production

The Aluminum Roof Stage Truss 18x12x10m from DragonStage is a high-performance staging solution specifically designed for major concerts, large-scale touring, and professional rigging applications. With substantial dimensions of 18m wide x 12m deep and an imposing 10m height, this system provides an expansive, structurally secure environment capable of supporting vast amounts of lighting, audio, and video equipment. It is engineered for event producers who require maximum load capacity and stability for complex, high-profile outdoor events.

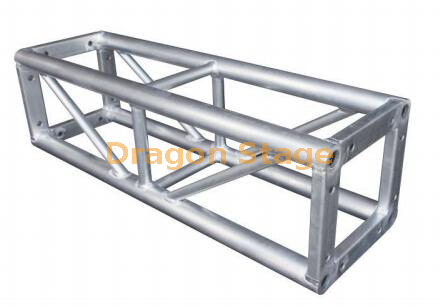

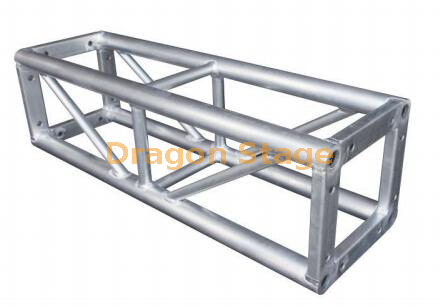

This system is distinguished by its use of the Bolt Truss System for primary connections, utilizing robust 350x350mm and 500x600mm standard lighting truss sections. The bolt connection is preferred in many heavy-duty applications for its high shear strength and precise, rigid coupling, making this structure a leading choice for concert stage truss rigging where structural integrity is non-negotiable.

2. Challenges & Solutions in Modern Event Construction

Large-format outdoor structures present unique challenges concerning structural deflection over long spans (like the 18m beam), managing high point loads from professional rigging, and ensuring structural stability in variable weather conditions.

DragonStage addresses these by employing a hybrid truss approach:

Heavy-Duty Span Management: BS500x600 square screw lighting truss is utilized for the main 18.00m and 12.00m beams, offering superior load-bearing capabilities and stability over long distances compared to smaller profiles.

Vertical Support: The system relies on six robust pillars built from BS350x350 screw aluminum lighting truss, which is essential for safely elevating the roof structure to the 10m height.

Connection Reliability: The use of a Bolt Truss System (also known as screw truss) ensures highly secure, permanent-feeling connections across the main load-bearing elements, critical for safe rigging in large concert settings (Source:https://www.dragontruss.com/Lighting-Truss-FAQ16138.html).

3. Key Features & Benefits

The 18x12x10m Truss System is a comprehensive package designed for professional deployment, combining a massive stage platform with an exceptionally robust roof structure.

High-Capacity Truss Structure

The main structural components are built to handle rigorous touring and rigging demands:

Main Beams: BS500x600 Square Screw Lighting Truss (50mm x 3.0mm main tubes) forms the 18.00m front and 12.00m side spans.

Pillars: BS350x350 Screw Aluminum Lighting Truss (50mm x 3.0mm main tubes) forms the six main 9.00m pillars.

Roof Grid: Built using BS300x300 Screw Lighting Truss for the roof frame and BL30 Aluminum I Truss with Bolt 300mm for the ladder truss sections, optimized for supporting distributed canopy and lighting loads.

Integrated Stage Deck and Ground Support

The system includes a substantial 16x11m stage system with an adjustable height from 1.2m to 2.0m. This flexibility is vital for establishing optimal sightlines for large audiences. The stage deck consists of 88 pieces of modular 1x2m wooden topping platforms. The roof structure is stabilized by a comprehensive ground support assembly, including 6 sets of Sleeve Blocks, Steel Bases, and Top Sections, supplemented by 24 Long Outriggers for maximum lateral stability.

Efficient Deployment and Safety Features

The entire structure is designed for field efficiency, with a total packing weight of 5200kg and a packing volume of 35CBM. Safe elevation of the heavy roof grid is controlled by 6 sets of 2-Ton Manual Hoists (BA05). Furthermore, the system includes a 350.16 sqm PVC roof canopy (available in blue or customized colors) for all-weather protection of high-value stage equipment. The structural components feature multiple truss options—including box truss, tri truss, and ladder truss—allowing for diverse rigging attachment points to meet any production spec (Source:https://www.prolight-sound.com).

4. Practical FAQ for Stage Professionals

Q: What is the primary advantage of the Bolt Truss System over Spigot Truss?A: Bolt truss offers a mechanically superior, more rigid, and inherently stronger connection, making it ideal for extremely heavy lifting and structures exposed to dynamic loading, often preferred for permanent installs or long-term outdoor events.

Q: Are there provisions for hanging line array speakers?A: Yes, the roof truss (BS500x600) is designed to handle high point loads, and specific rigging points (often using Single/Double Clamps) must be calculated and attached to the main beam truss sections for speaker arrays.

Q: Is the stage height adjustable within the 1.2m to 2.0m range?A: Yes, the stage uses stand with extendable tube components and Stage adjustable base units, allowing for precise height setting and leveling within that range.

Q: What is the recommended method for load testing this structure?A: Load testing should always be performed according to manufacturer specifications and certified by a structural engineer, applying test loads in excess of the maximum calculated payload to verify the integrity of the truss and connections before rigging commences.

5. Strong Call to Action (CTA)

For your next major concert event or touring production, secure the high load capacity and unmatched stability of the DragonStage Aluminum Roof Stage Truss 18x12x10m.

Consult with our technical experts today for a full rigging capacity assessment and project-specific pricing.