Heavy Duty Outdoor Stage Roof Truss System: The 14x7x9m Concert Solution

1. Introduction

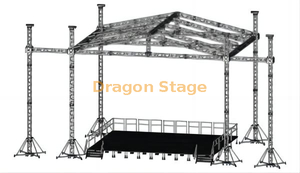

For large-scale events, from music festivals and concerts to high-profile exhibitions, the stage structure must be an unparalleled fusion of size, stability, and speed. DragonStage’s 14x7x9m outdoor stage roof truss system delivers precisely that. Engineered to cover a performance area of approximately 80 square meters (12.2m x 6.1m stage area), this imposing structure provides the robust overhead support required for heavy lighting rigs, line arrays, and video screens. It is the definitive portable curved roof truss system for event professionals who require TUV-certified engineering, rapid deployment, and uncompromising audience and performer safety.

2. Industry Challenges & Professional Solutions

Event contractors and stage builders frequently confront three major pain points: managing the logistical complexities of oversized equipment, ensuring the structural integrity of temporary outdoor installations, and rapid setup/teardown. A structure of this scale introduces significant wind load risks, demanding superior engineering.

DragonStage provides a powerful solution by leveraging high-grade aluminum truss (utilizing main tubes of 50x3.0mm) combined with an intelligent structural design. The system incorporates robust outriggers and steel bases designed for effective weight distribution and foundational stability, mitigating risks associated with uneven ground. Furthermore, the truss components, including the primary CS389x389 beams and CS289x289 pillars, are manufactured for precision assembly, allowing experienced crews to realize the substantial 14x7m concert truss structure with minimal downtime. The entire system is built to meet global safety standards, including TUV, SGS, and CE certifications, providing professional assurance and peace of mind (Source:https://www.dragontruss.com/TUV-Report-dc249965.html).

3. Key Features & Operational Benefits

The 14x7x9m outdoor stage roof truss system is a comprehensive solution, meticulously designed for maximum performance in high-stakes environments.

Engineered Load Capacity and Component Integration

The structure's core stability relies on heavy-duty truss sections and mechanical support components. It is not just a stage but a complete high-load capacity outdoor truss system, including two dedicated 2m-wide speaker truss wings integrated seamlessly into the main 14m-wide frame. This integration ensures the safe suspension of line array speakers, maintaining proper acoustics and preventing excessive point loads on the main roof. The main structural components, typical of DragonStage’s offerings, use high-strength aluminum, providing a lightweight yet durable frame optimized for repeated use (Source:https://www.dragontruss.com/Aluminum-Truss-pl3962133.html).

All-Weather Protection and Rapid Rigging

The system features a curved roof stage platform design, which is highly effective for water runoff and provides an aesthetically pleasing backdrop for performances. The PVC roof canopy protects expensive technical equipment—such as lighting, sound systems, and video walls—from adverse weather, a necessity for any temporary concert venue structure. For efficient lifting, the system is equipped with robust components like Sleeve Blocks, Steel Bases, and manual 2-ton hoists, enabling precise and safe rigging operations in adherence to industry standards, which recommend thorough checks of load tables and rigging integrity before any lift (Source:https://www.plasa.org). The modularity of the design, from the 25 individual 4x8ft wooden stage platforms to the bolted truss connections, translates directly to faster setup, minimizing on-site labor costs and accelerating project completion.

4. Practical FAQ for Stage Professionals

| Question | Answer |

| Q: What is the load capacity of the roof? | The certified load capacity depends on the distribution and specific rigging points. Detailed static calculations are provided in the TUV documentation. |

| Q: Is the stage height adjustable? | While the roof height is fixed at 9m, the stage platform (12.2m x 6.1m) typically offers adjustable leveling feet for stabilization on uneven outdoor surfaces. |

| Q: How does the system handle wind loads? | This structure is designed with long outriggers and steel bases to anchor the system, providing enhanced stability and mitigating potential wind uplift forces as certified by our engineering reports. |

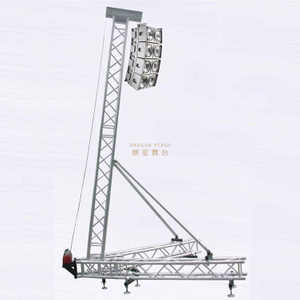

| Q: What are the main components for lifting? | The roof is lifted using a hinge section and manual 2-ton hoists (4 units), facilitating safe and controlled vertical assembly. |

5. Strong Call to Action (CTA)

Don't compromise on the safety and structural integrity of your large-scale events. Choose a certified, professional-grade solution built for rapid deployment and maximum load capacity.

Download detailed specifications and contact DragonStage’s engineering team today to design your custom outdoor stage platform.