packing weight: 2100kg

packing volume: 21cbm

| Item |

| Specification(squre truss) | Qty |

| length | main tube(mm) | size(mm) |

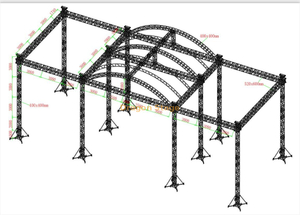

| 9.00 m Beam(side) | 2 sets | 3.00 m | 50×3.0 | CS389×389 | 6 pcs |

| 2.00 m | 50×3.0 | CS389×389 | pcs |

| 1.00 m | 50×3.0 | CS389×389 | pcs |

| 6.00 m Pillar | 4 sets | 3.00 m | 50×3.0 | CS289×289 | 8 pcs |

| 2.00 m | 50×3.0 | CS289×289 | pcs |

| 1.00 m | 50×3.0 | CS289×289 | pcs |

| Tower | Spigot Sleeve Block S | 4 pcs |

| Steel Base S | 4 pcs |

| Top Section S | 4 pcs |

| Manual hoist,BA05 2Tons | 4 pcs |

| Spigot Hinge Section,Height 1m | 4 pcs |

| Fibre sling,BA04,2 tons 3m | 4 pcs |

| Long outrigger | 16 pcs |

| Item |

| Specification(squre truss) | Qty |

| length | main tube(mm) | size(mm) |

| 16.00 m Arch Beam | 6 sets | 3.00 m | 50×3.0 | CS289×289 | 28 pcs |

| 2.00 m | 50×3.0 | CS289×289 | 28 pcs |

| 1.00 m | 50×3.0 | CS289×289 | 6 pcs |

| 9.00 m Connect Rod | 7 sets | 3.00 m | 50×3.0 | - | 28 pcs |

| 2.00 m | 50×3.0 | - | 7 pcs |

| 1.00 m | 50×3.0 | - | pcs |

| Roof Components |

| 3 Ways corner, use for roof beam truss | CS389×389 | 11 pcs |

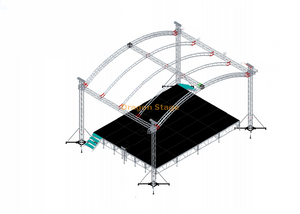

| roof canopy material:pvc, Blue Colour or customized. | 199.75 | 1 pcs |

| Truss Accessory |

| Conical coupler & Safrty clip & pin | whole

set |

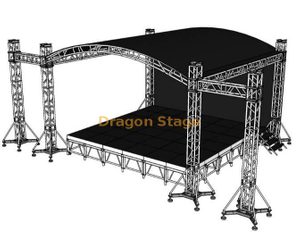

Truss Material: High-strength steel or aluminum are likely the best choices for this project due to their strength-to-weight ratio and resistance to corrosion. The selection will depend on specific load calculations and environmental factors.

Truss Design: A combination of triangular and curved sections will likely be used to create a strong and visually appealing structure. The truss system should be designed with multiple support points to distribute the load effectively and minimize stress on individual elements.

Roofing Material: The choice of roofing material will depend on the desired aesthetic and the need for weather protection. Lightweight yet durable options such as stretched fabric or polycarbonate panels could be ideal, providing excellent weather resistance and visual appeal.

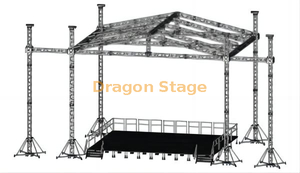

Lighting and Sound Integration: The truss system should be designed to accommodate lighting fixtures and sound equipment. The integration must be carefully planned to ensure optimal performance and visual impact while maintaining structural integrity.

Construction and Installation:

The construction and installation of the curved roof truss system require a skilled team of engineers, fabricators, and installers. Here are some important aspects:

Pre-fabrication: To ensure accuracy and efficiency, the truss elements should be pre-fabricated off-site. This allows for meticulous quality control and reduces the time required for on-site construction.

On-site Assembly: On-site assembly requires a comprehensive plan and a skilled team. Lifting and positioning the heavy truss sections will require specialized equipment and a safe work plan.

Rigging and Testing: Once the truss system is assembled, it will undergo rigorous testing to ensure its load-bearing capacity and stability.